Automatic

assembly

equipment

Plastic part

heating and transfer

equipment

Jigs and

inspection

gauges

Heating and

firing transfer

equipment

Powder

feeders

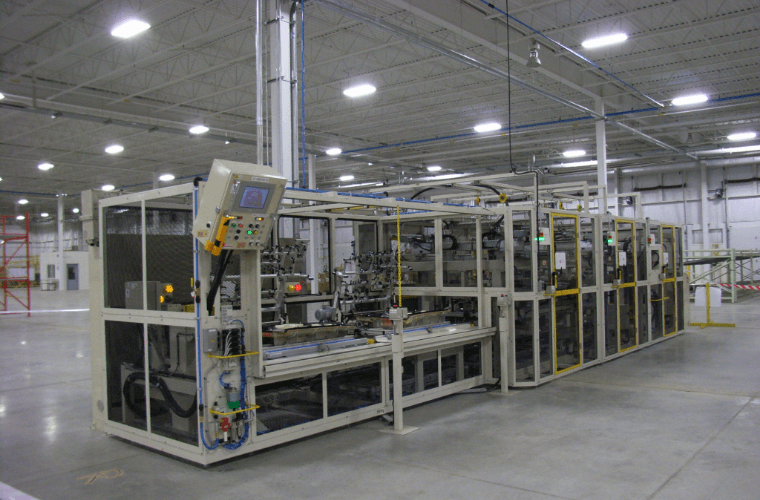

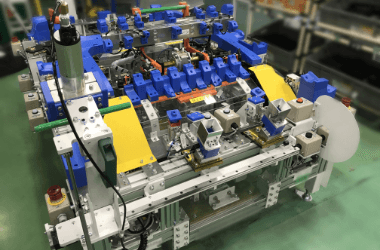

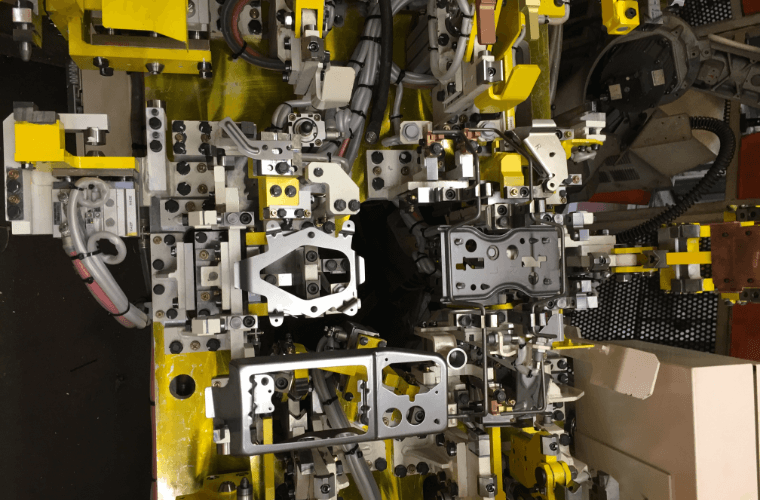

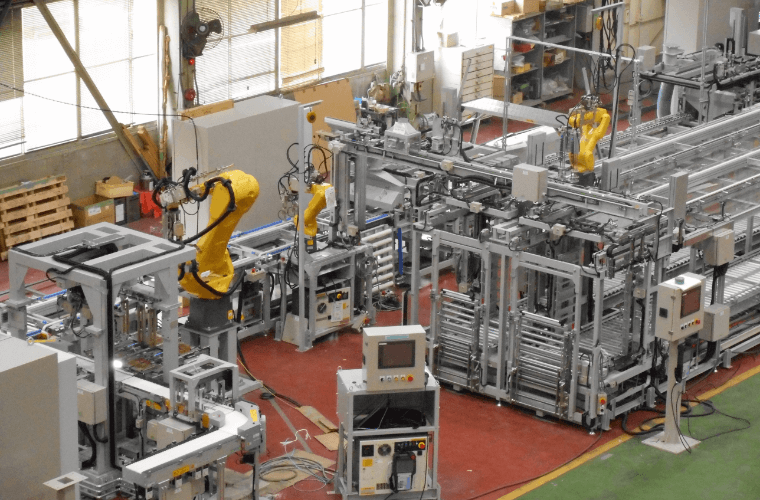

Automatic assembly equipment

TAKAHAMA provides equipment for automatically transferring products,

as well as equipment for performing such processes as welding, press fitting, and screw fitting automatically.

Door trim assembly equipment

Processes such as ultrasonic molding and caulking, screw tightening, retainer insertion, and W/S claw bending are performed by robots, and all kinds of door trim can be assembled fully-automatically.

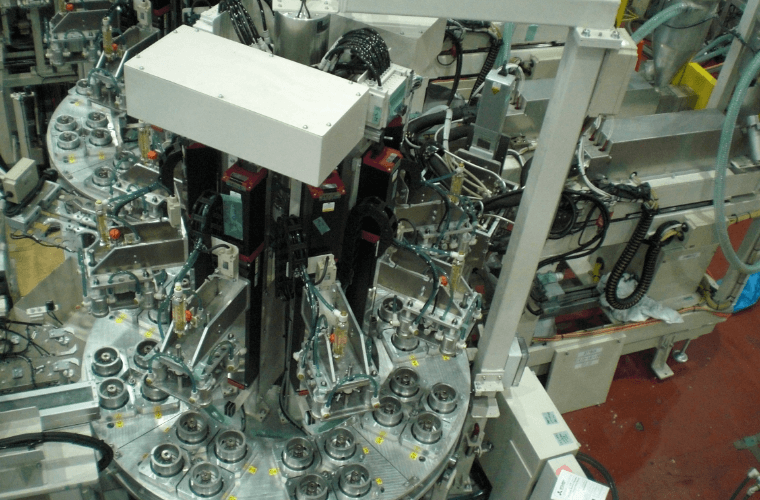

Functional part assembly equipment

This line is used to perform the following processes automatically.

Press fitting: Parts are press fit while controlling torque with a motor-driven cylinder.

Grease application: Grease is applied by a robot.

Screw tightening: An automatic screw tightening unit employs a robot to automatically tighten screws.

Filter assembly equipment

This production line is used to wash materials, drill holes, and apply a liquid gasket. It automatically assembles component parts, and applies coating, dries, prints, and packages fully-automatically.

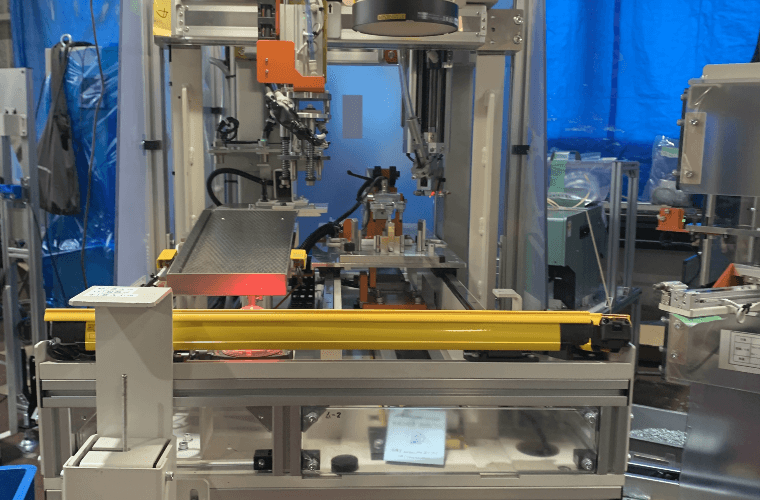

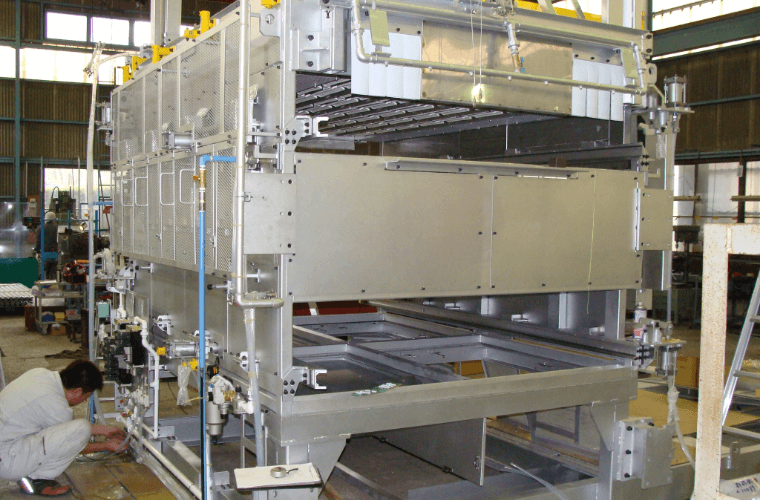

Plastic part heating and transfer equipment

TAKAHAMA provides equipment for transferring plastic-formed parts between presses, heating equipment, and equipment for carrying out all processes after forming is complete.

Forming equipment

This automatic line feeds and heats materials, transfers workpieces between presses, and then removes them. It is also equipped with a function for automatically changing production parts.

Main materials: fabrics, films, thermoplastic resin sheets

Post-forming machining equipment

This is a stand-alone unit used for product assembly.

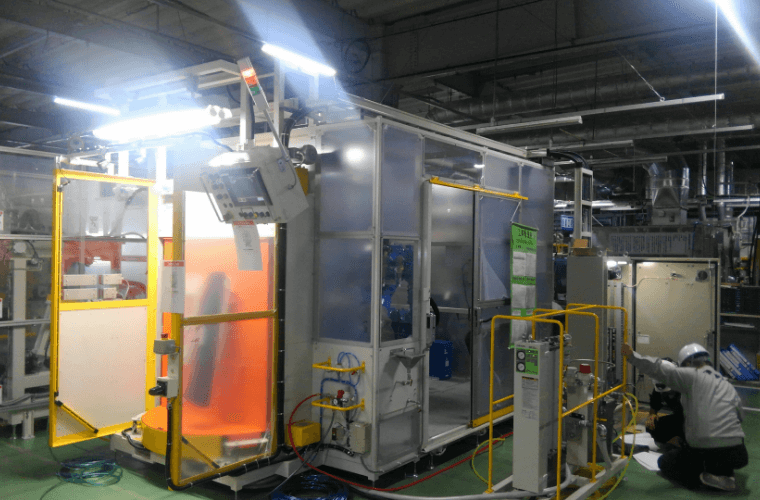

Heating equipment

TAKAHAMA provides heating equipment that uses different heaters to suit the workpiece.

Glue applying machine

TAKAHAMA also uses robots to manufacture application masking jigs to suit 3D shaped workpieces.

Glue dryer

Atmospheric drying is used to dry glue. TAKAHAMA also manufactures specially-shaped nozzles to apply hot air only to specific parts of workpieces.

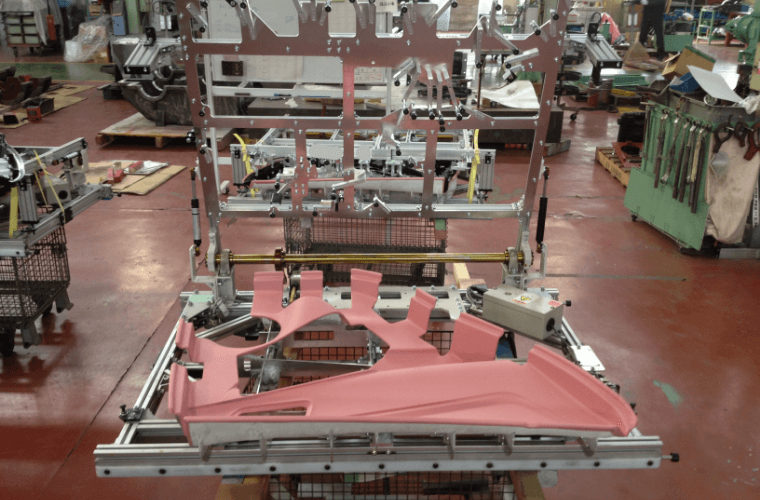

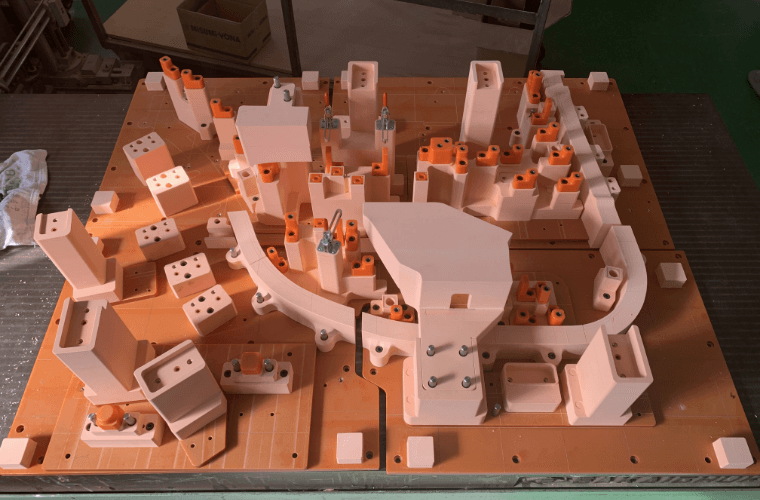

Jigs and inspection gauges

TAKAHAMA offers a wide range of plastic molds such as equipment jigs, jigs to help workers, and inspection jigs.

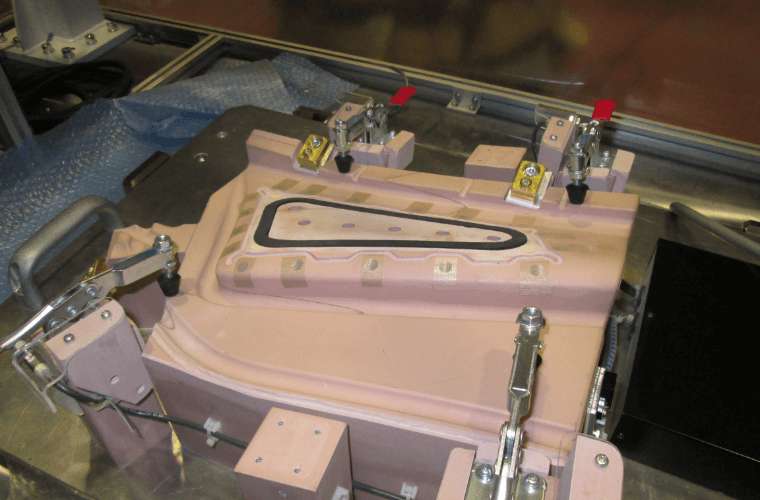

Door trim assembly jigs

TAKAHAMA also manufactures moulds for holding workpiece positioning jigs for robotic welding and clip insertion using materials such as carbon, FRP, and resin blocks.

External bonding jigs

These jigs are used to pressure bond substrates and exterior coatings such as resin blocks and aluminum.

Bonding jigs

These masking jigs are used to separate areas into those to which glue is applied and those to which no glue is applied.

Welding jigs

These jigs are used to clamp and position component parts.

Plastic dimension gauges

These inspection jigs are used to measure the length and other dimensions of all parts such as the outer perimeter and cross section.

Heating and firing transfer equipment

TAKAHAMA provides transfer equipment for ceramic products that can be prone to deformation and cracking.

Ceramic product automatic loading and unloading equipment

TAKAHAMA has built an automatic loading and unloading line which uses a robot to perform high-performance vision inspection of ceramic products which can be prone to contraction and deformation. This line is compatible with 600 types of products using control and ID management.

Ceramic product automatic loading and unloading equipment

TAKAHAMA has built an automatic loading and unloading line which uses a robot to perform high-performance vision inspection of ceramic products which can be prone to contraction and deformation. This line is compatible with 600 types of products using control and ID management.

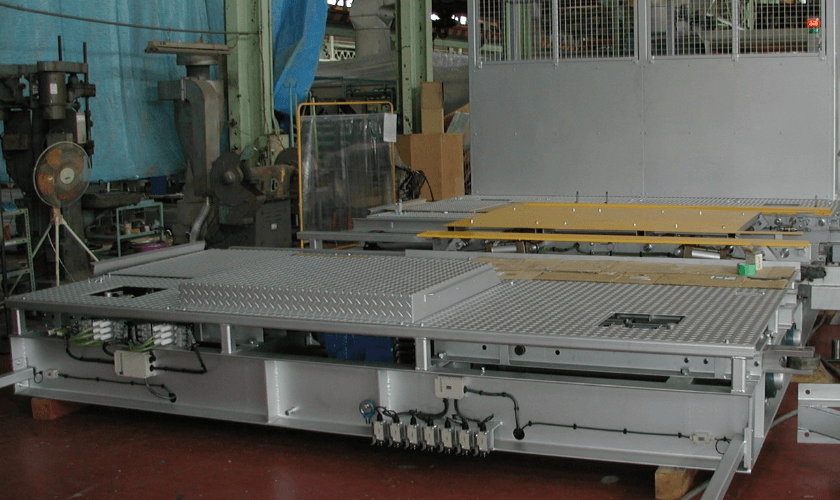

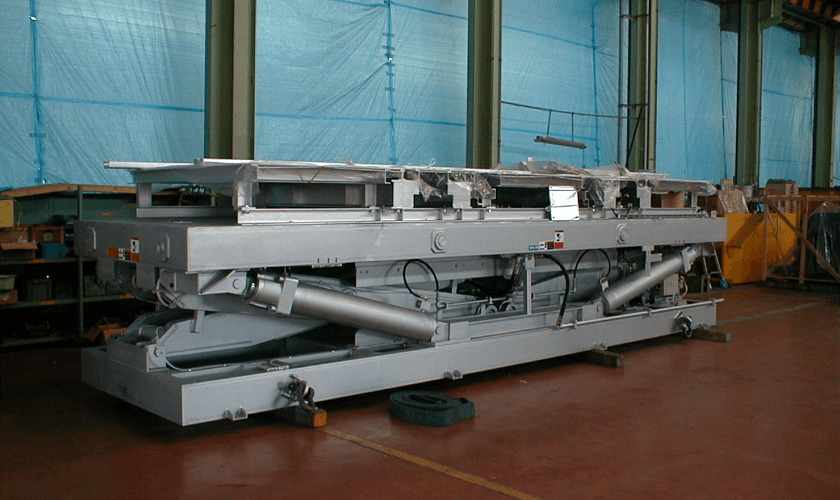

Large transfer cars

Large lifters

These heat-resistant, low-vibration lifters are capable of conveying heavy products weighing up to approximately 10 tons.* Heavy products are conveyed with level of stability that would not knock over a φ20 by 150 mm long round bar.

Dryers

TAKAHAMA’s dryers have a wide guard area, and are capable of drying a wide range of materials including ceramics, electronic materials, fertilizer, and wood meal.

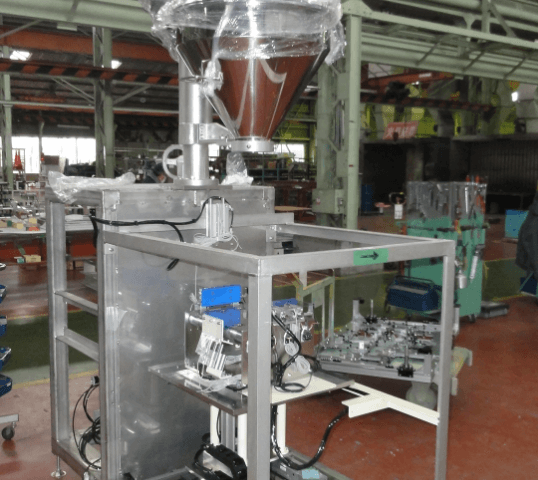

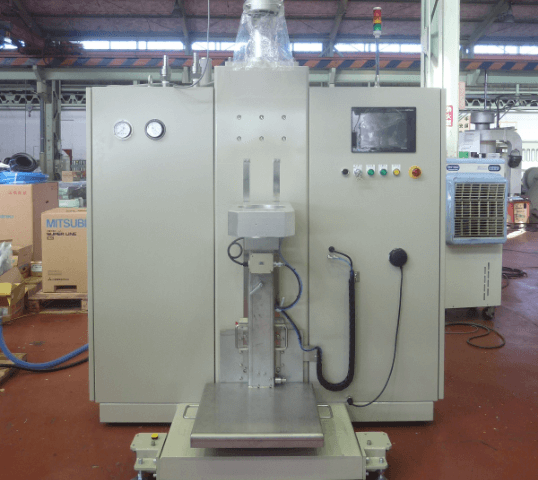

Powder feeders

TAKAHAMA’s powder feeders are capable of feeding precise quantities of powder.

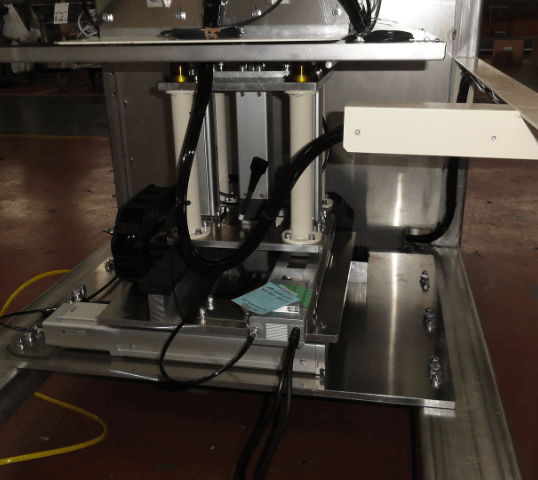

Lifting equipment

Filling machines

Measuring instruments

The fluidity of low-fluidity substances is improved by rotating a screw part prior to discharge, allowing quantitative

filling of powdered fillers to be performed by simultaneously measuring the prescribed quantity.

Filling machine capacity measurement is performed either based on the number of screw rotations, or by weighing

the substance using a weighing scale.