Hot Forging

Cold forging

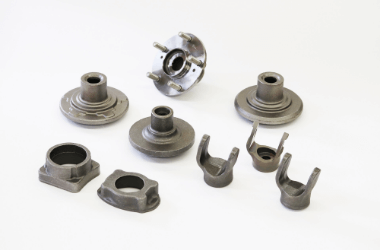

Hot Forging

Hot forging involves heating iron to 1,200 ºC or higher, and then press-forming it with a mould.

It is used for parts that require high strength and toughness.

Automobiles - chassis

TAKAHAMA manufactures forged chassis parts that are resistant to rapid EV and hybrid vehicle torque, and that enable stable driving in all speed ranges.

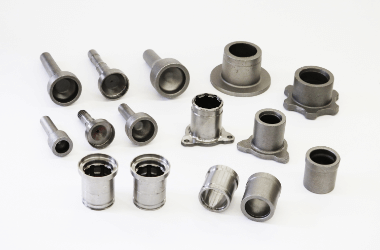

Automobiles - constant velocity joints

Power transmission parts (constant velocity joints) are indispensable parts for both EVs and gasoline-powered vehicles.

Transmissions(SUVs, trucks)

TAKAHAMA produces SUV and truck transmission parts that are indispensable for driving in deserts and mountain ranges that are not suitable for EVs.

Non-automotive

(building components, construction machinery, bicycles, industrial robots, etc.)

- TAKAHAMA forged parts that are used in non-automotive field -

Construction parts (tunnel wall material joints), construction machinery and forklifts (transmission gears), electric vehicles (gears), power tools (air joints), etc.

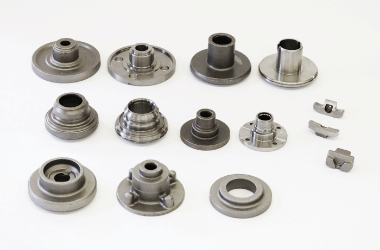

Cold forging

Cold forging involves press-forming material at room temperature with a mould.

TAKAHAMA has two part formers, and uses them to quickly mass produce parts with complex shape.

Automobile parts

TAKAHAMA produces anti-vibration rubber core shafts, hydraulic valve joints, and power window motor shafts.

Non-automotive

Agriculture tractor parts, industrial robot parts (reducer gears), OA equipment and printer parts