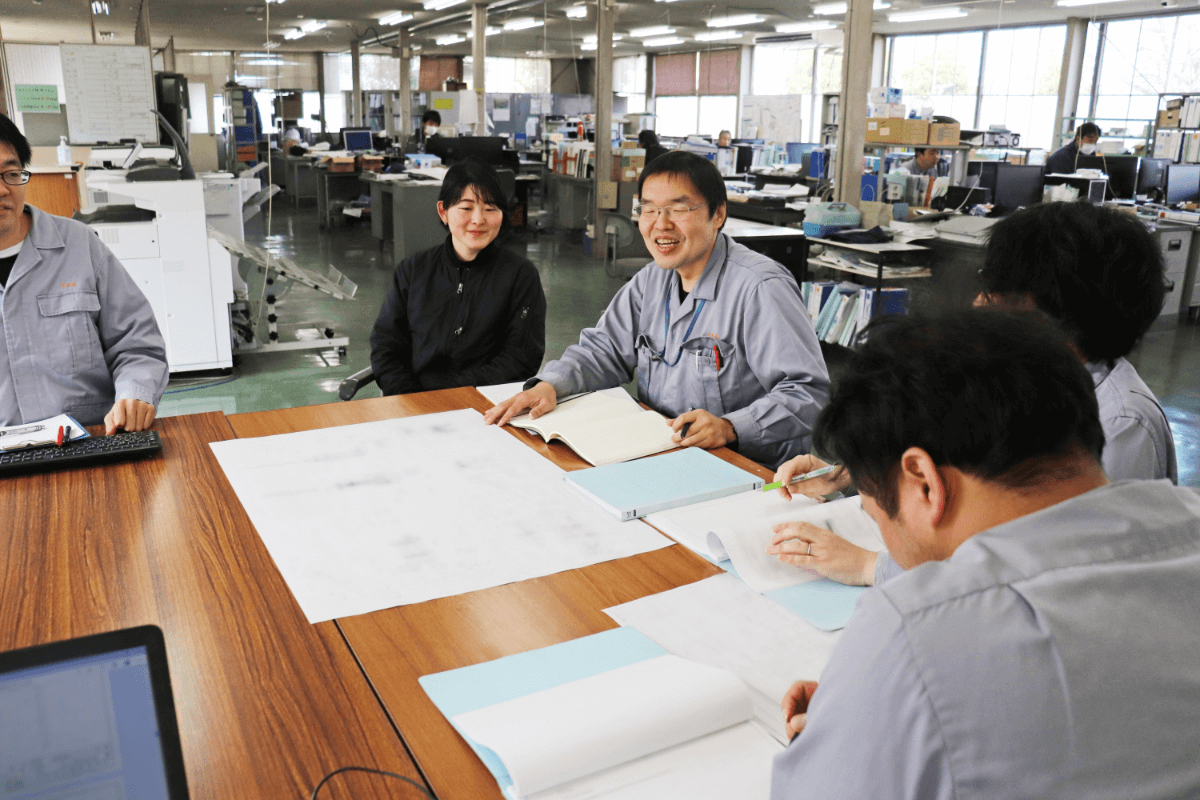

As an all-around plant manufacturer, we in the Industrial Machinery Division handle all processes from research and development, to marketing, design, manufacture, and after-sales service in house.

As a leading company in the industry, we have been supporting the manufacturing industry with our advanced technology not only in Japan, but also overseas.

We have delivered equipment to more than 38 countries, and our products are known affectionately all over the world by the “KAJISEKI” brand name.

We have leveraged our pulverizing, mixing, forming, drying, inspection, and transfer process technology which we have cultivated in the field of traditional ceramics such as ceramics, roofing tiles, and tiles, to promote technological innovation in a wide range of fields including fine ceramics such as honeycomb and insulators, and industrial equipment designed for labor savings.

As an all-around plant manufacturer, we in the Industrial Machinery Division handle all processes from research and development, to marketing, design, manufacture, and after-sales service in house. As a leading company in the industry, we have been supporting the manufacturing industry with our advanced technology not only in Japan, but also overseas. We have delivered equipment to more than 38 countries, and our products are known affectionately all over the world by the “KAJISEKI” brand name. We have leveraged our pulverizing, mixing, forming, drying, inspection, and transfer process technology which we have cultivated in the field of traditional ceramics such as ceramics, roofing tiles, and tiles, to promote technological innovation in a wide range of fields including fine ceramics such as honeycomb and insulators, and industrial equipment designed for labor savings.

Design

2D-CAD (CADPAC),

3D-CAD (ICAD/CATIA)

Machine design,

electrical design, robot program design

Machine design:

19 people, electrical design: 12 people

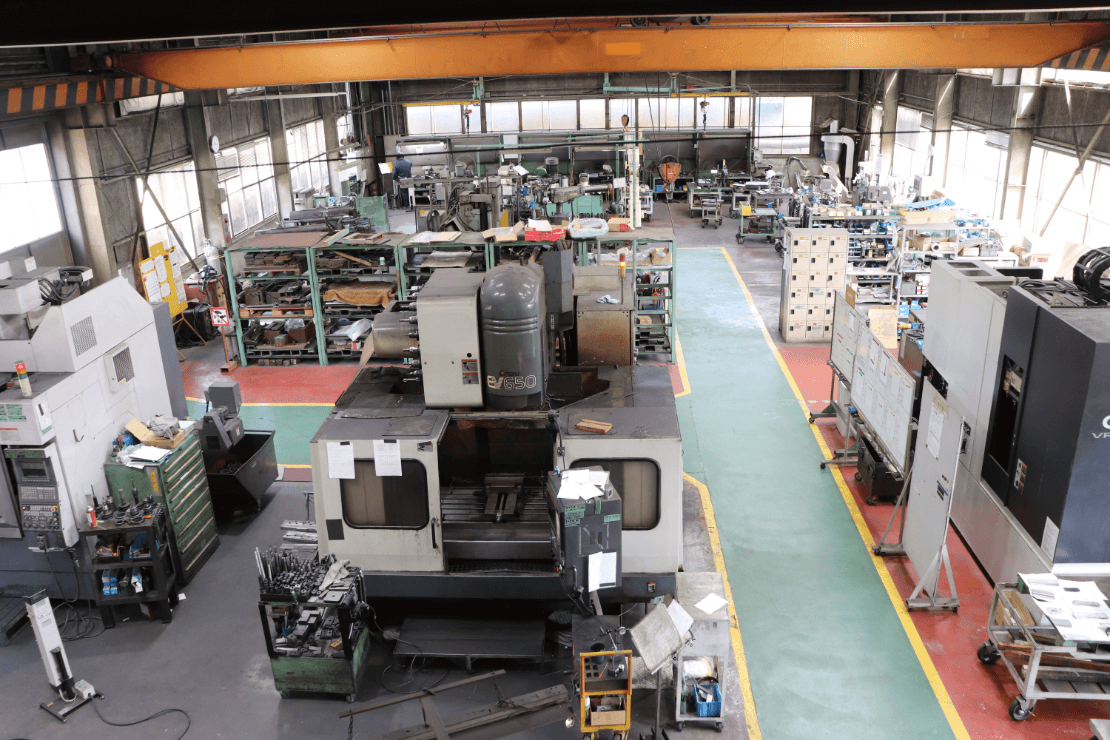

Factory size

Premises: 74,475 m²

Factory: 18,205 m²

Assembly plant

Max. space: 93 x 51 m Max. height: 15 m Max. overhead traveling crane payload: 15 tons

Export Countries

USA, Canada, Mexico, Brazil, Venezuela, Argentina, Colombia, Poland, Belgium, Austria, New Zealand, South Africa, Egypt, Turkey, Jordan, Iran, Bangladesh, Pakistan, India, Sri Lanka, Thailand, Indonesia, Vietnam, Malaysia, Philippines, South Korea, Taiwan, China, etc.

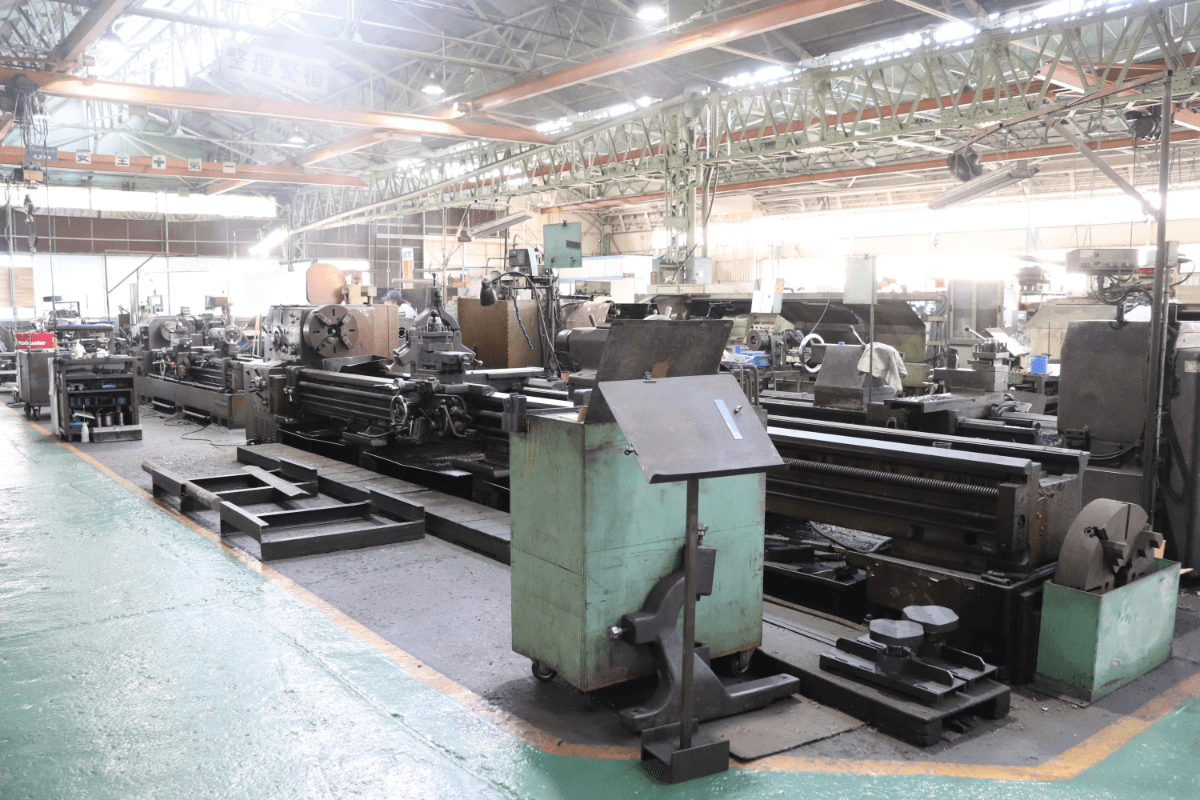

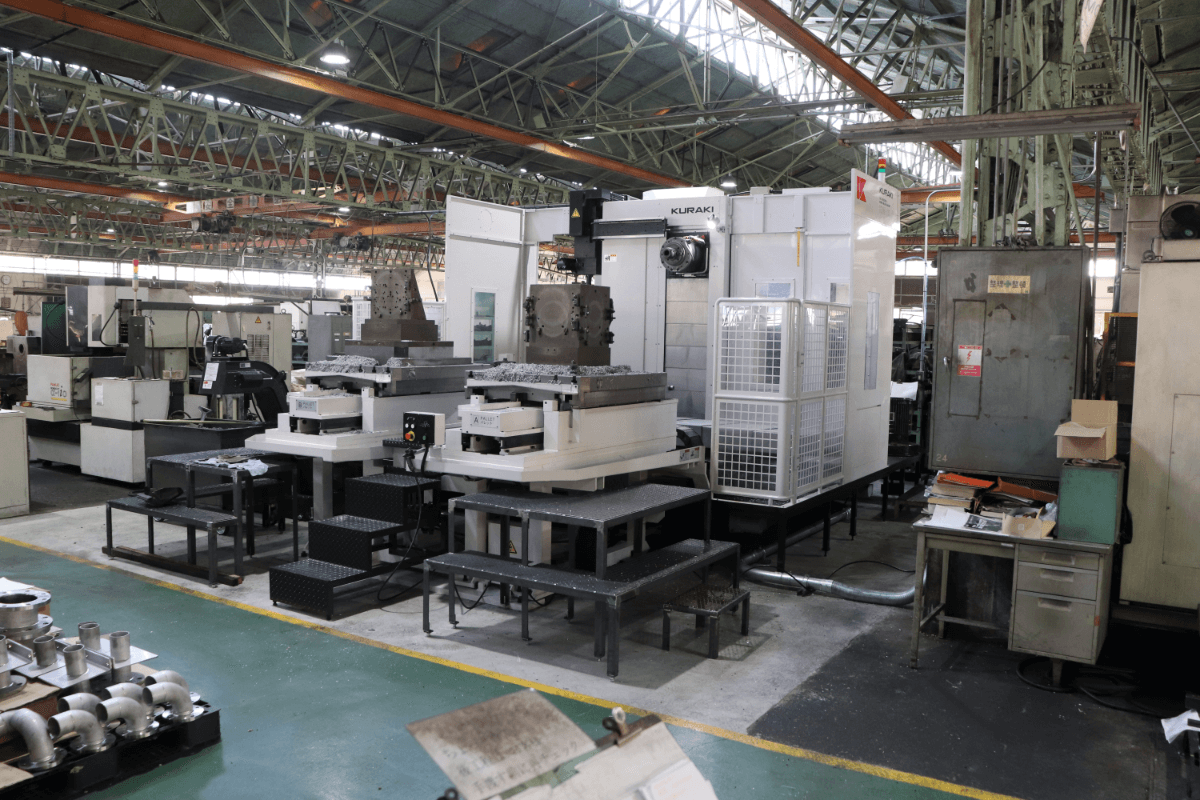

Main Machining Equipment

Dedicated long object lathe

1* Capable of machining objects up to 5,000 mm.

NC lathes

5* Capable of machining small to large objects up to 3,000 mm in length.

NC lathes: 3 CNC lathes: 2

Welding machines

6* Capable of welding large cans.

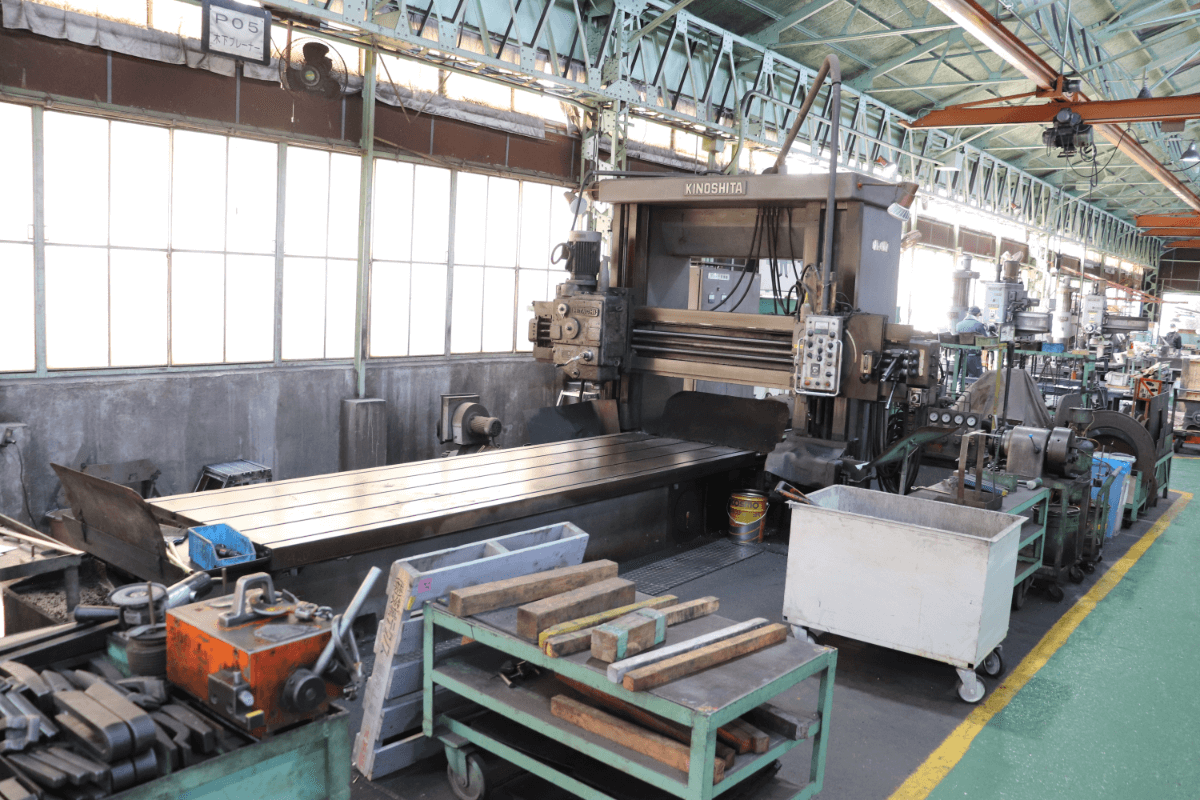

Large planomiller

1* Machining area: 1,200 x 4,000 mm

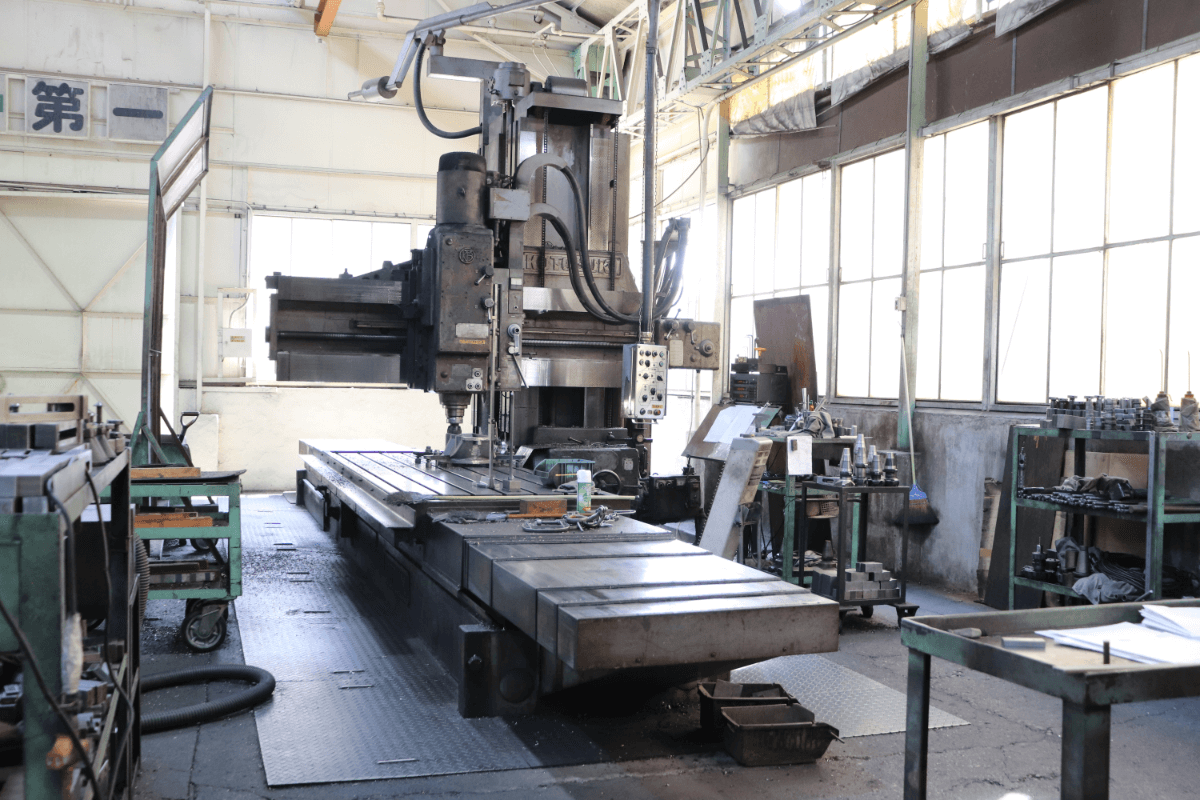

Gantry planomiller

1* Machining area: 1,200 x 4,000 mm

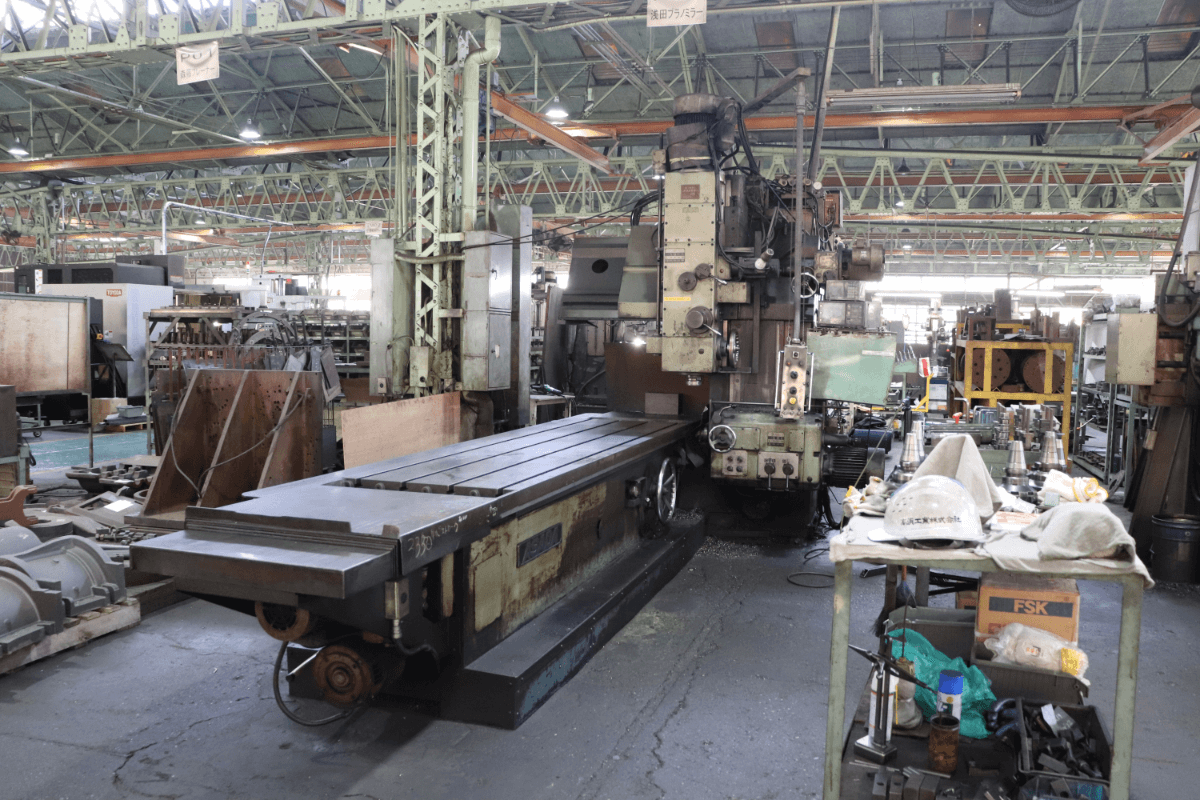

Planomillers

4* Machining area: 1,000 x 3,000 mm

CNC horizontal boring milling machines2

Dedicated long object lathe

NC lathes

Welding machines

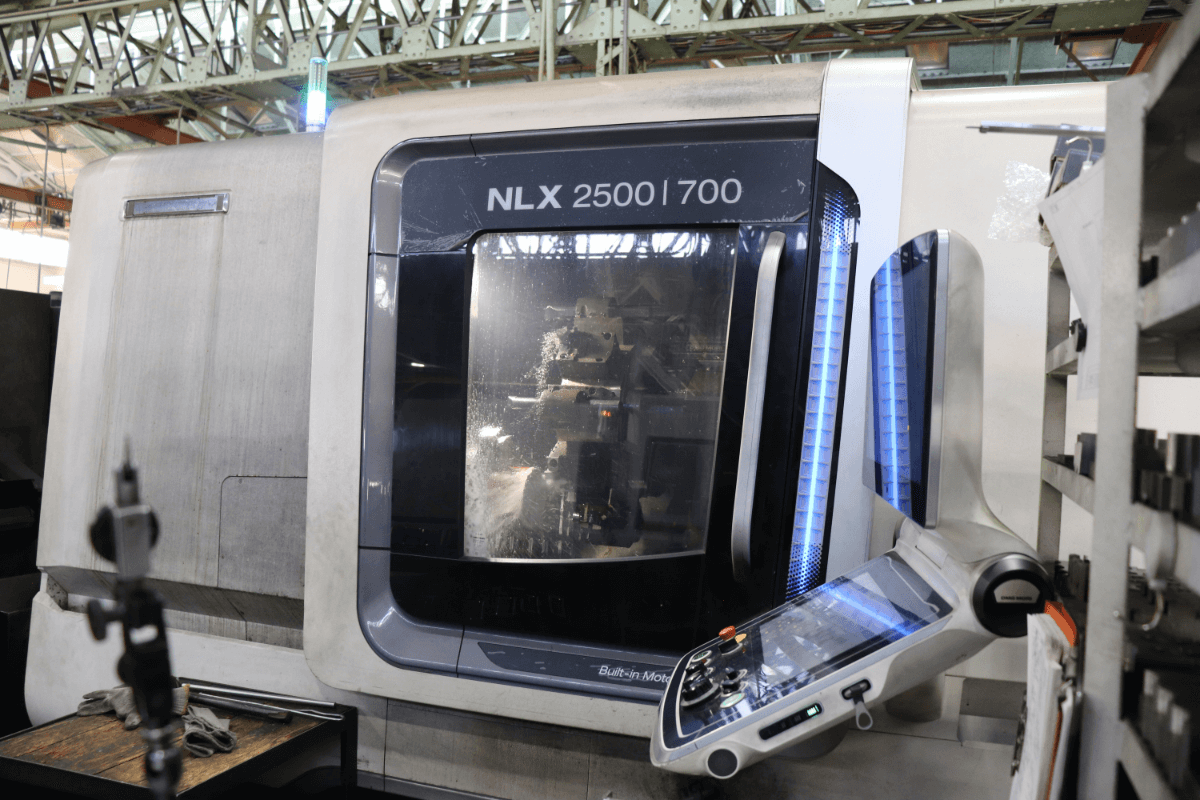

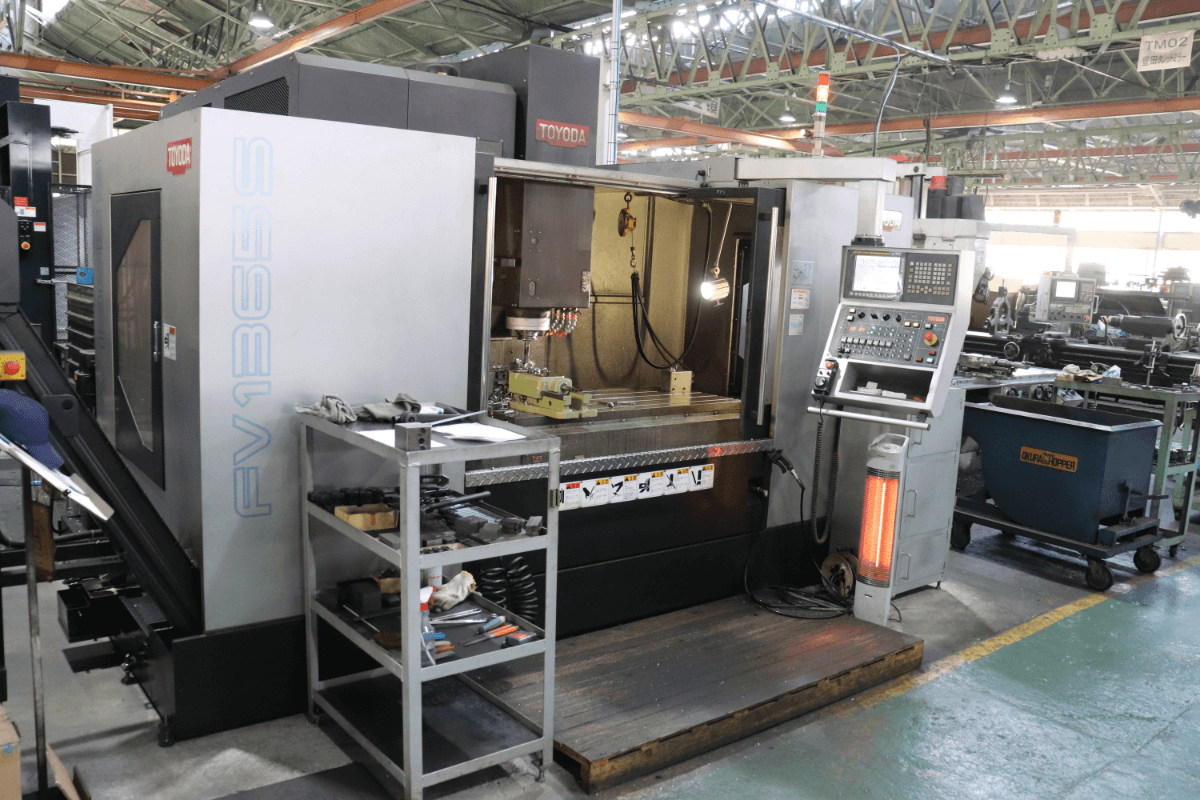

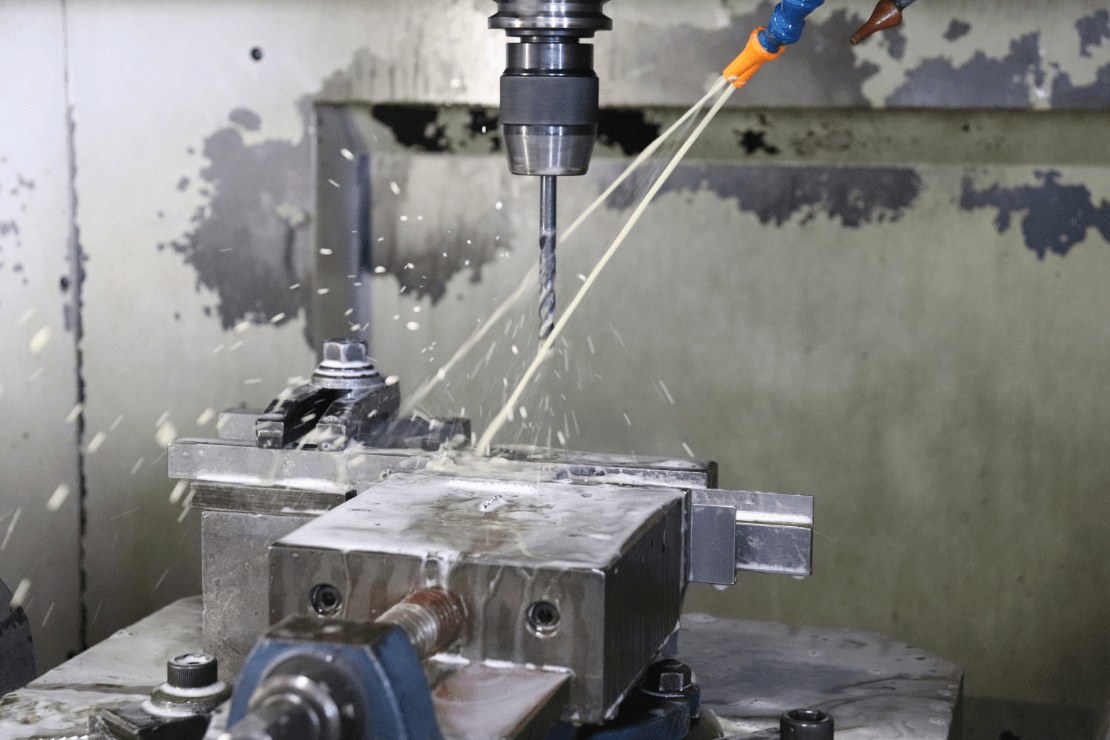

Vertical machining centers

Large planomiller

Gantry planomiller

Planomillers

CNC horizontal boring milling machines

NC machines

* Machining area: 762×460×460 mm

5-axis NC machines:2 3-axis NC machines:1

Electric discharge machines

* Machining area: 400 x 300 x 550 mm

5-axis NC machines:2

5-axis NC machines:2

Vertical machining centers