Plants

We propose line configurations to meet customer needs using TAKAHAMA INDUSTRY’s traditional technical expertise and wealth of experience.

"KAJISEKI" brand equipment, which boasts reliability and an impressive track record, is loved throughout the world, and has been shipped to 38 countries worldwide.

Ceramics manufacture

Our plants can manufacture ceramic products such as tableware, plant pots, and umbrella stands without the need for experienced engineers.

Clay feeder

De-airing extruder

Clay cutting and

feeding machine

Roller forming

machine

High-speed

leather-hard dryer

Primary hot air

generator

Primary transfer

machine

Edge finishing

machine

Secondary transfer

machine

Product conveyor

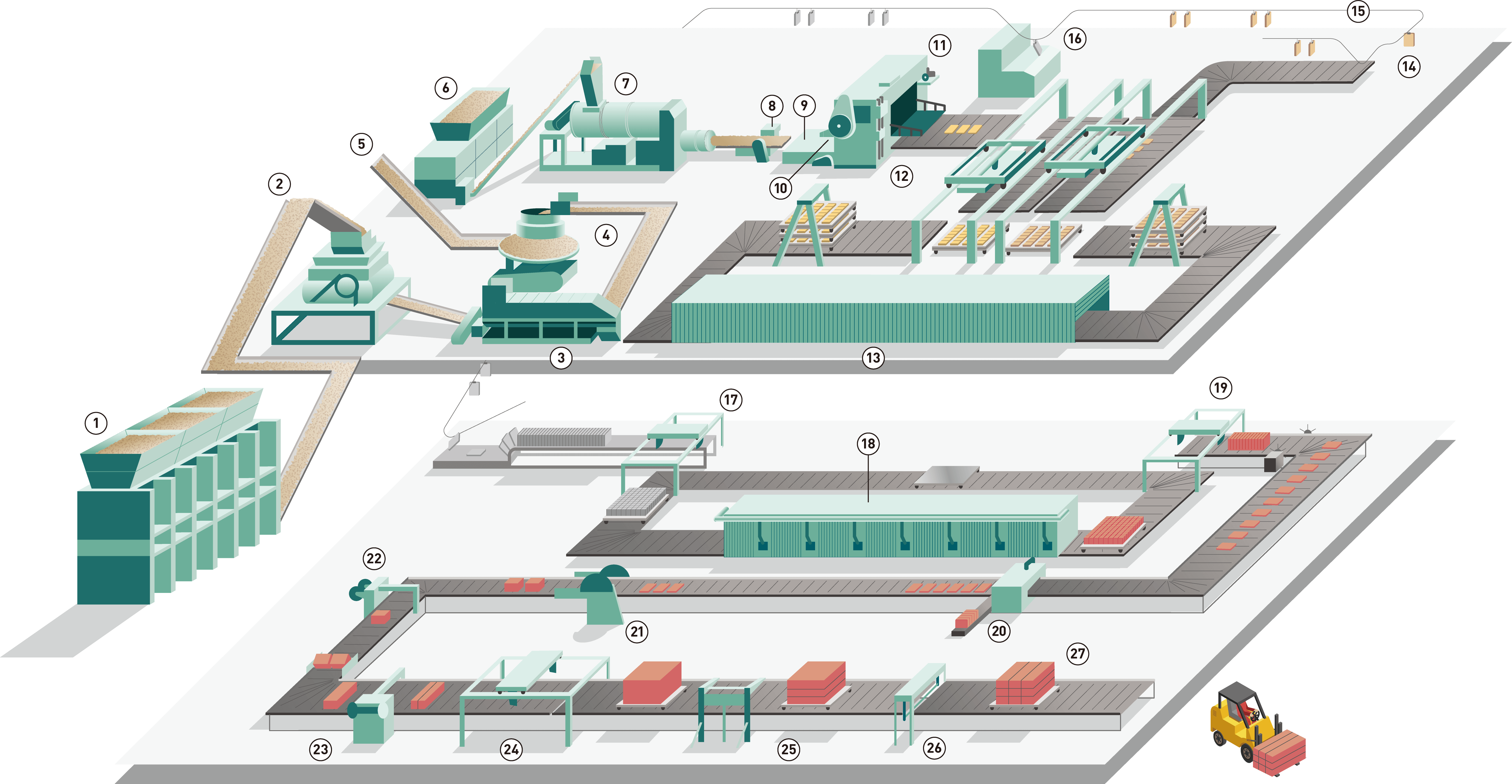

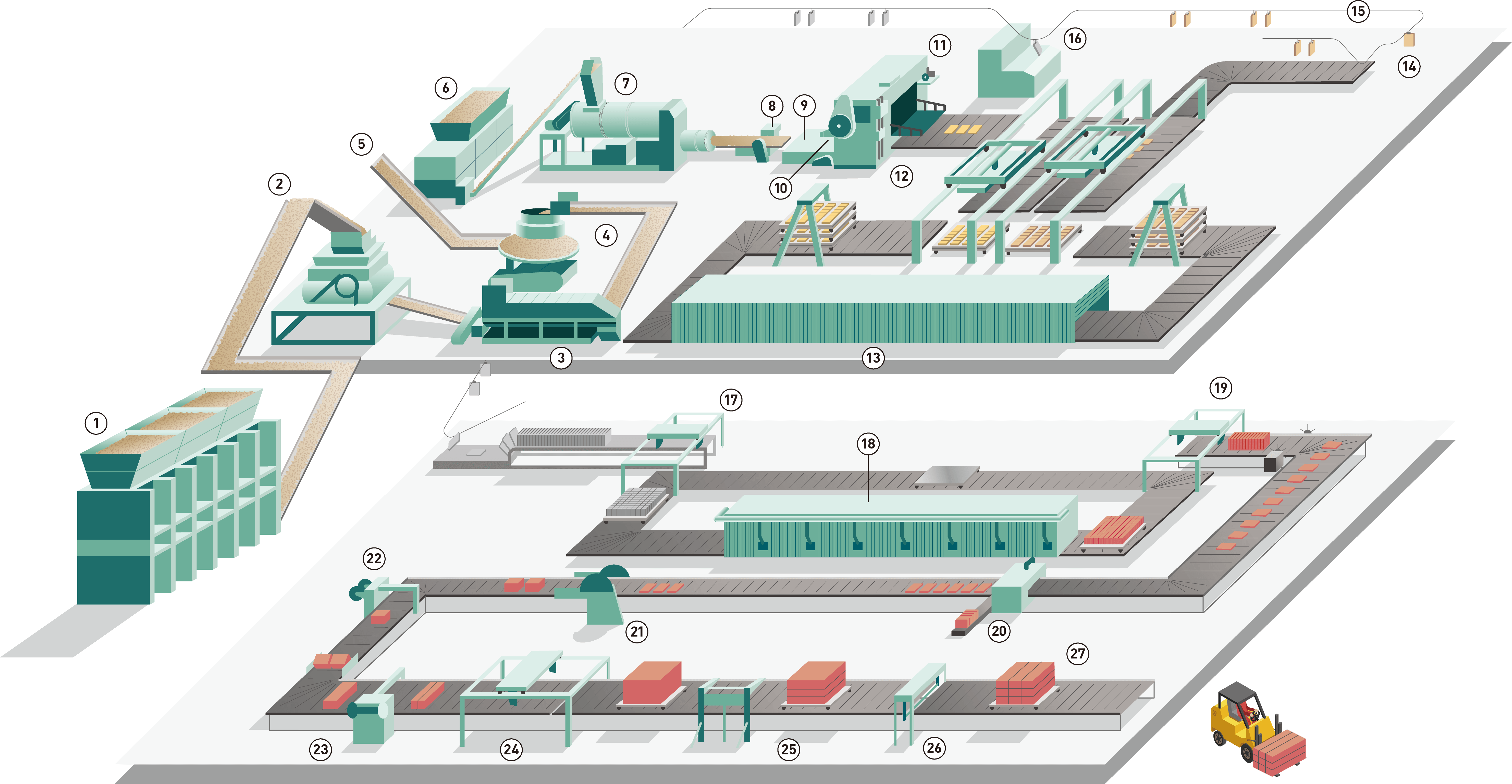

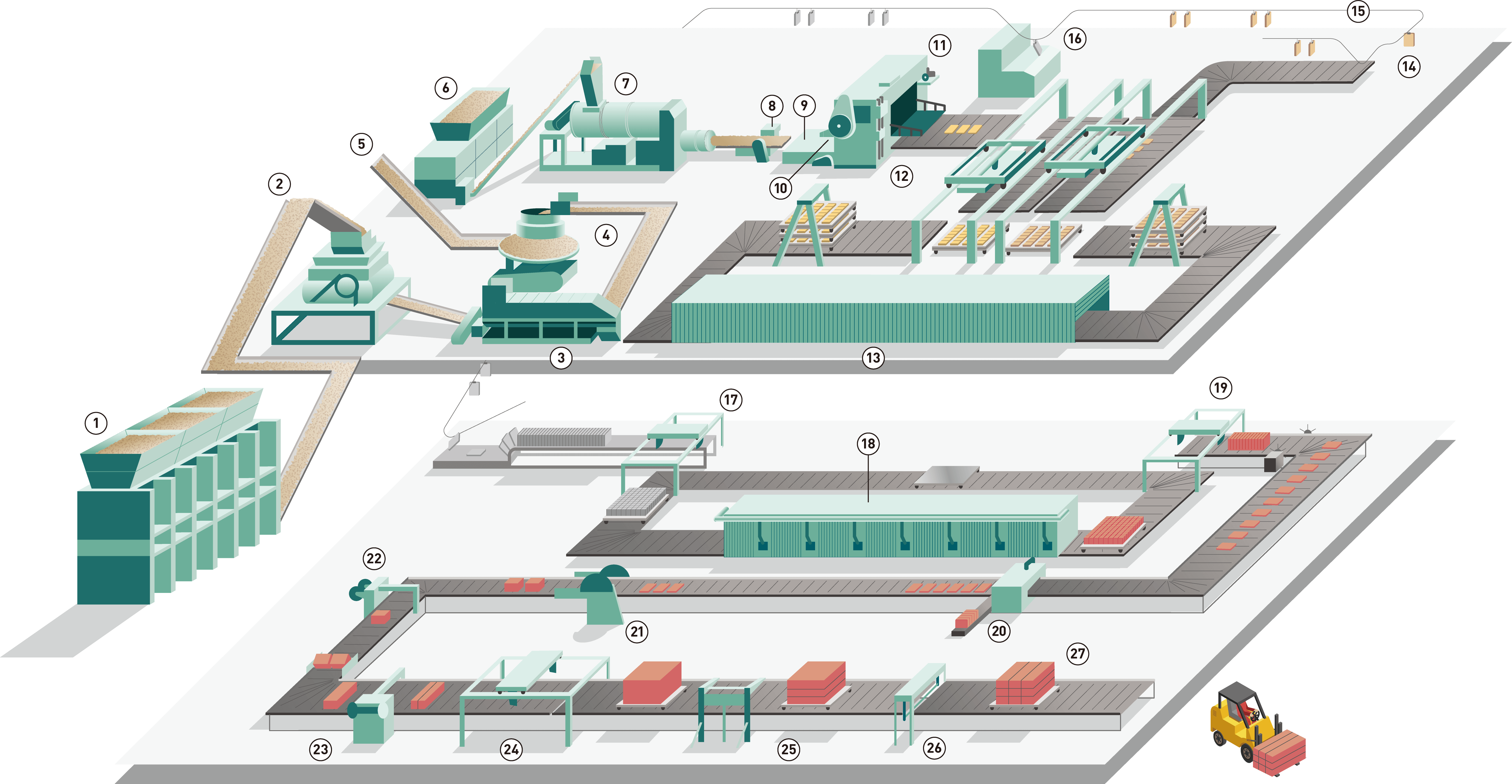

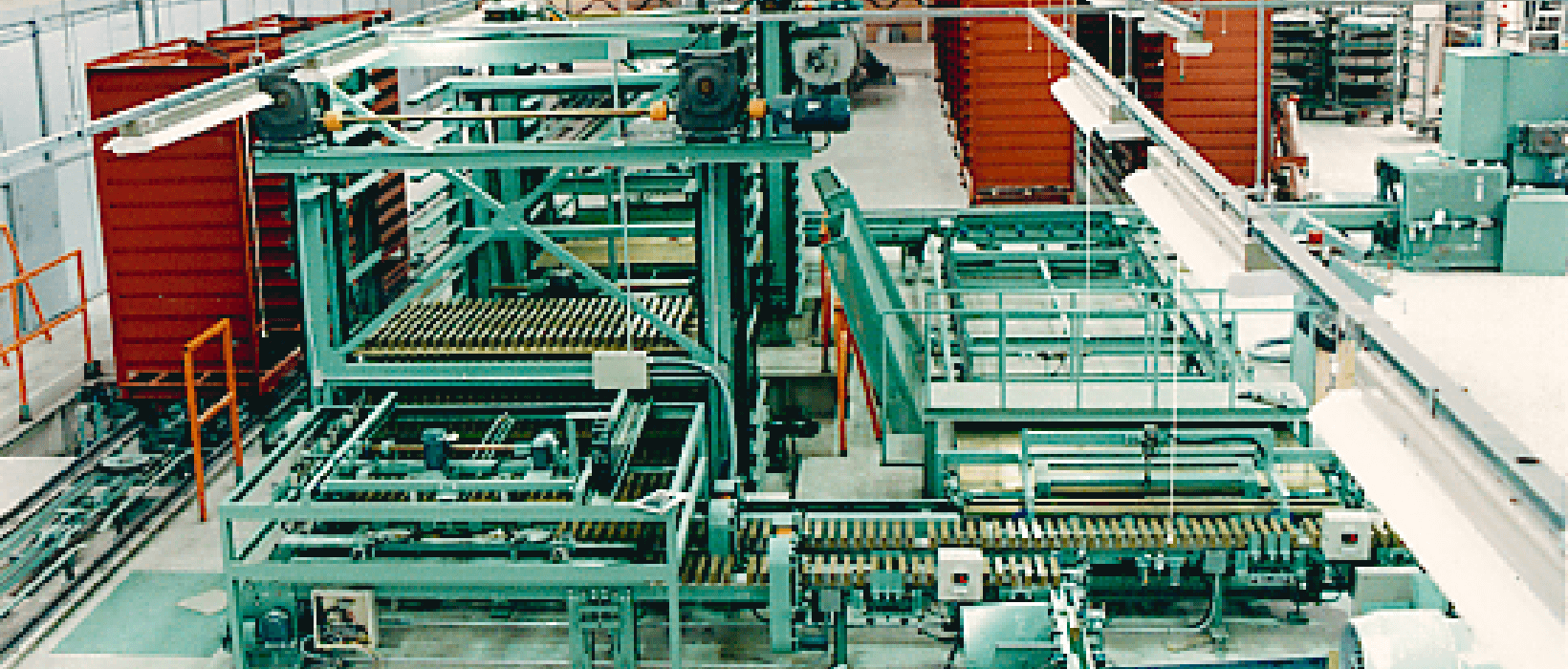

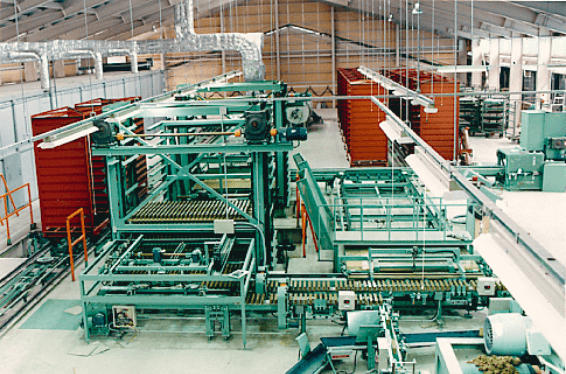

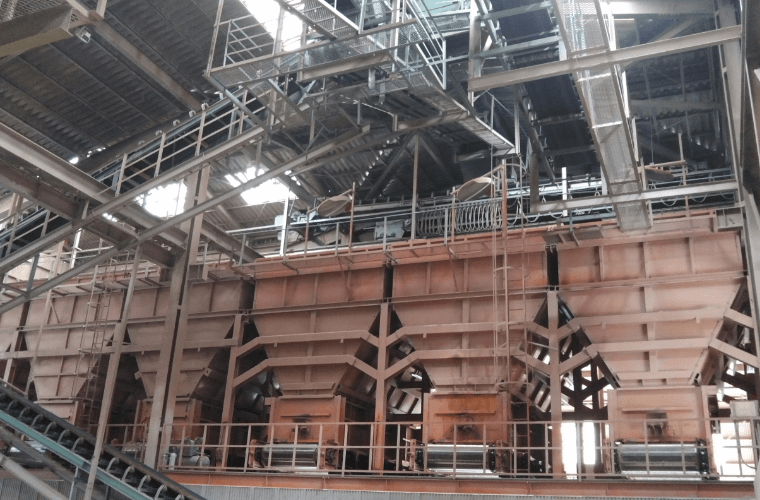

Roofing tile manufacture

Our plants can manufacture all kinds of roofing tile including J-shaped tiles, S-shaped tiles, F-shaped tiles, disaster prevention tiles, and accessory tiles fully-automatically and efficiently.

1.Box feeder

2.Roll crusher

3.Mixing pug mill

4.Screen feeder

5.Stockyard

6.Feeder

7.Vacuum-type

de-airing extruder

8.Clay cutter

9.Green body

distributor

10.Green body

feeder

11.Press molding

machine

12.Formed ware

loading unit and

greenware unloader

13.Fully-automatic

high-speed dryer

14.Auto chucker

15.Hanger line

16.Glazing machine

17.Greenware loading

unit

18.Tunnel kiln

19.Fired product

unloader

20.Fired product

inspection machine

21.4-layer stacker

22.4-layer binding

machine

23.Single-row

binding machine

24.Bound product

loader

25.Horizontal binding

machine

26.Vertical binding

machine

27.Shipping conveyor

Tile manufacture

Our plants can manufacture all kinds of tile including mosaic tiles, exterior wall tiles, interior wall tiles, and accessory tiles fully-automatically and efficiently.

Clay feeder

Mixing pug mill

Vacuum extrusion

forming machine

Chamfering machine

Clay cutter

Loading unit

Fully-automatic

high-speed dryer

Unloading unit

Setter loader

Sub-dryer

Roller hearth kiln

Setter unloader

Inspection machine

Binding machine

Packing

Shipping

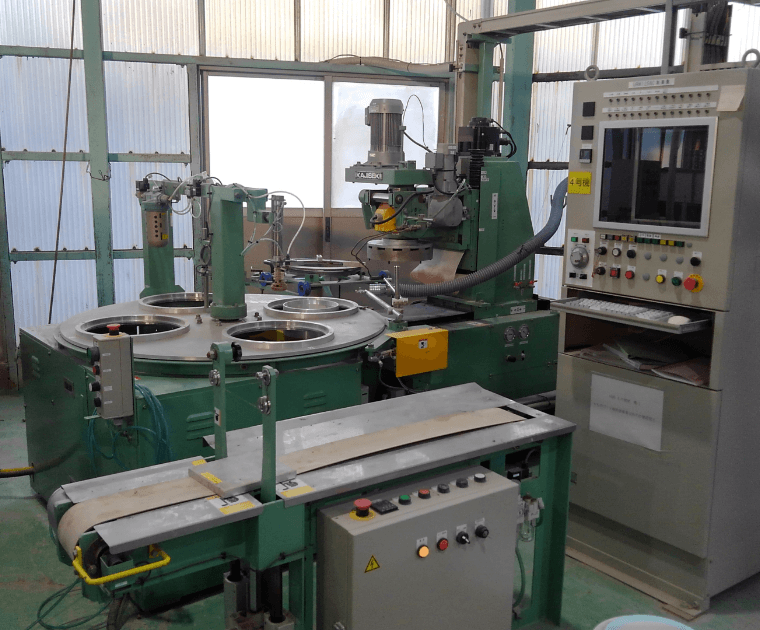

Forming equipment

TAKAHAMA boasts forming equipment capable of handling ceramics and roofing tile product shapes, as well as equipment capable of meeting tight customer production schedules.

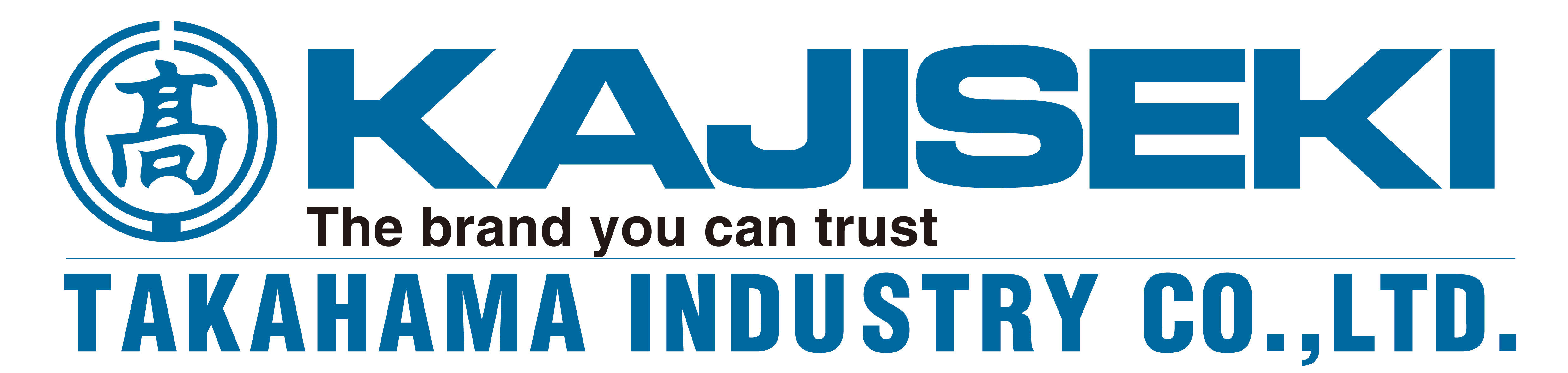

Stand-alone forming machine for tableware

This machine is ideal for high-mix low-volume production.

It is capable of both inner trowel and outer trowel production.

It performs forming using the arc slide method or NC method. Arc slide method: Minute roller head movements are realized

with a slide mechanism.

NC method: Adjustments can be made easily by anyone

simply by entering numerical values. The UR50 has been exported to and is used in more than 30 countries, and is a highly-reliable cam type roller machine.

Stand-alone forming machine for tableware

This machine is ideal for high-mix low-volume production. It is capable of both inner trowel and outer trowel production. It performs forming using the arc slide method or NC method.

Arc slide method:

Minute roller head movements are realized with a slide mechanism.

NC method:

Adjustments can be made easily by anyone simply by entering numerical values. The UR50 has been exported to and is used in more than 30 countries, and is a highly-reliable cam type roller machine.

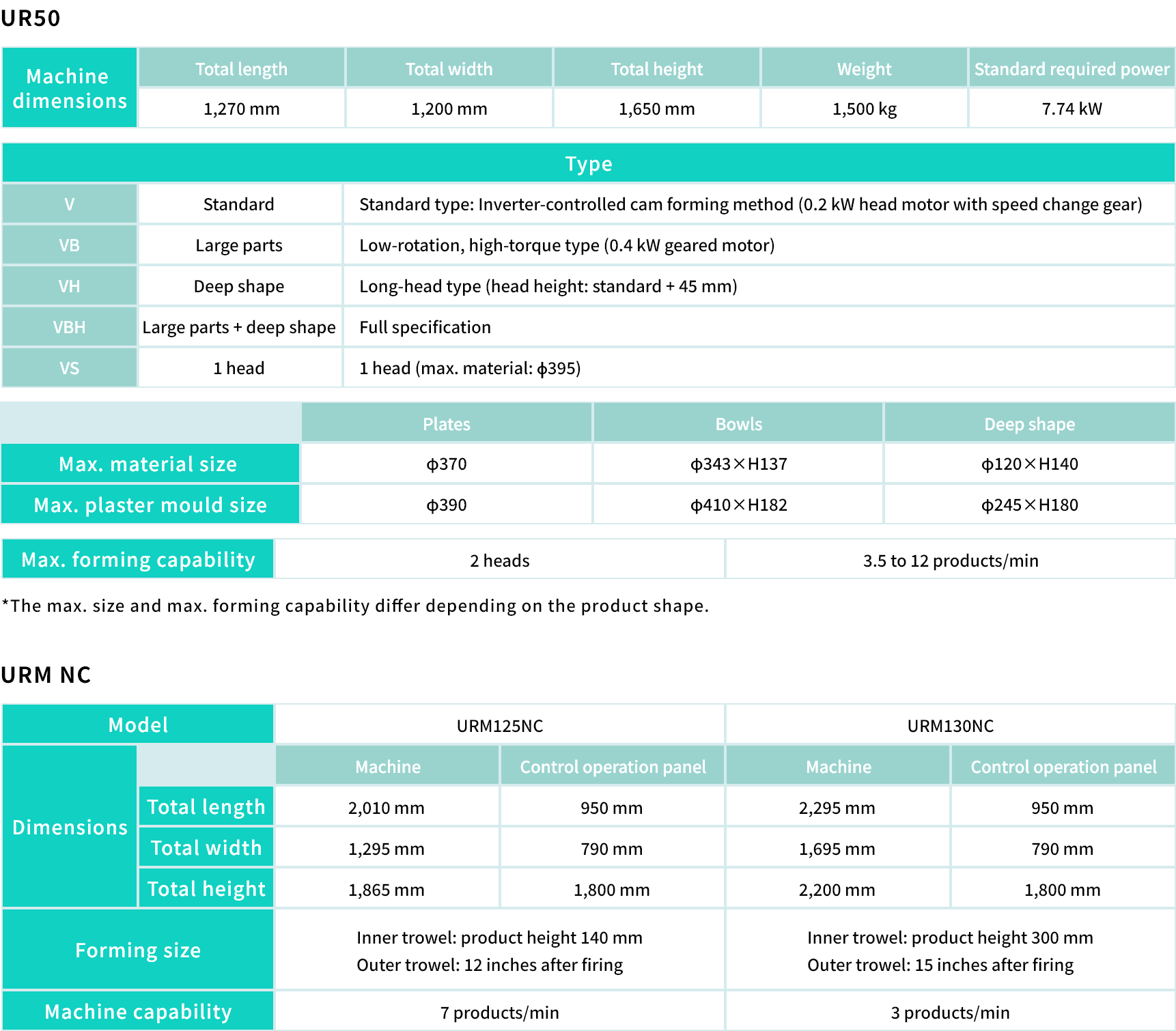

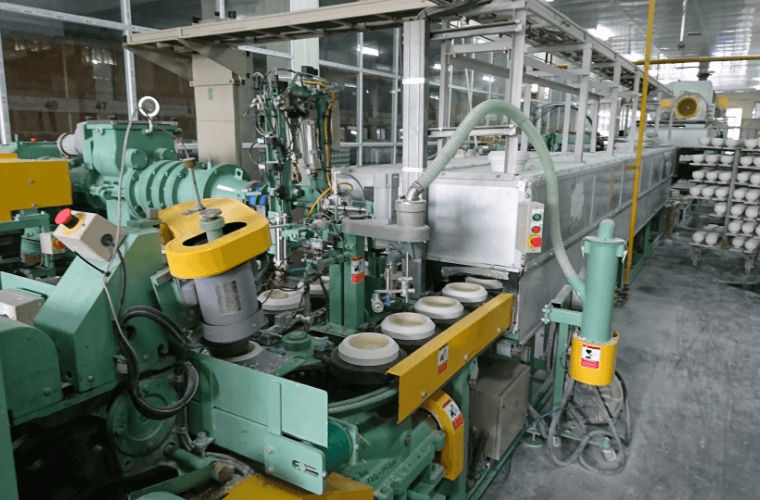

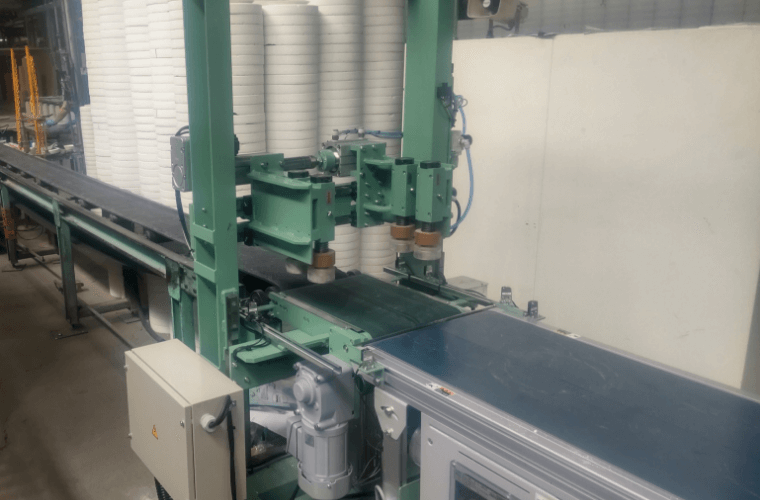

Fully-automatic manufacturing system for tableware

This system performs a series of processes from clay feeding to forming, drying, and edge shaping. The equipment is both compact and labor-saving. The machines that make up the system can be selected to meet customer requirements.

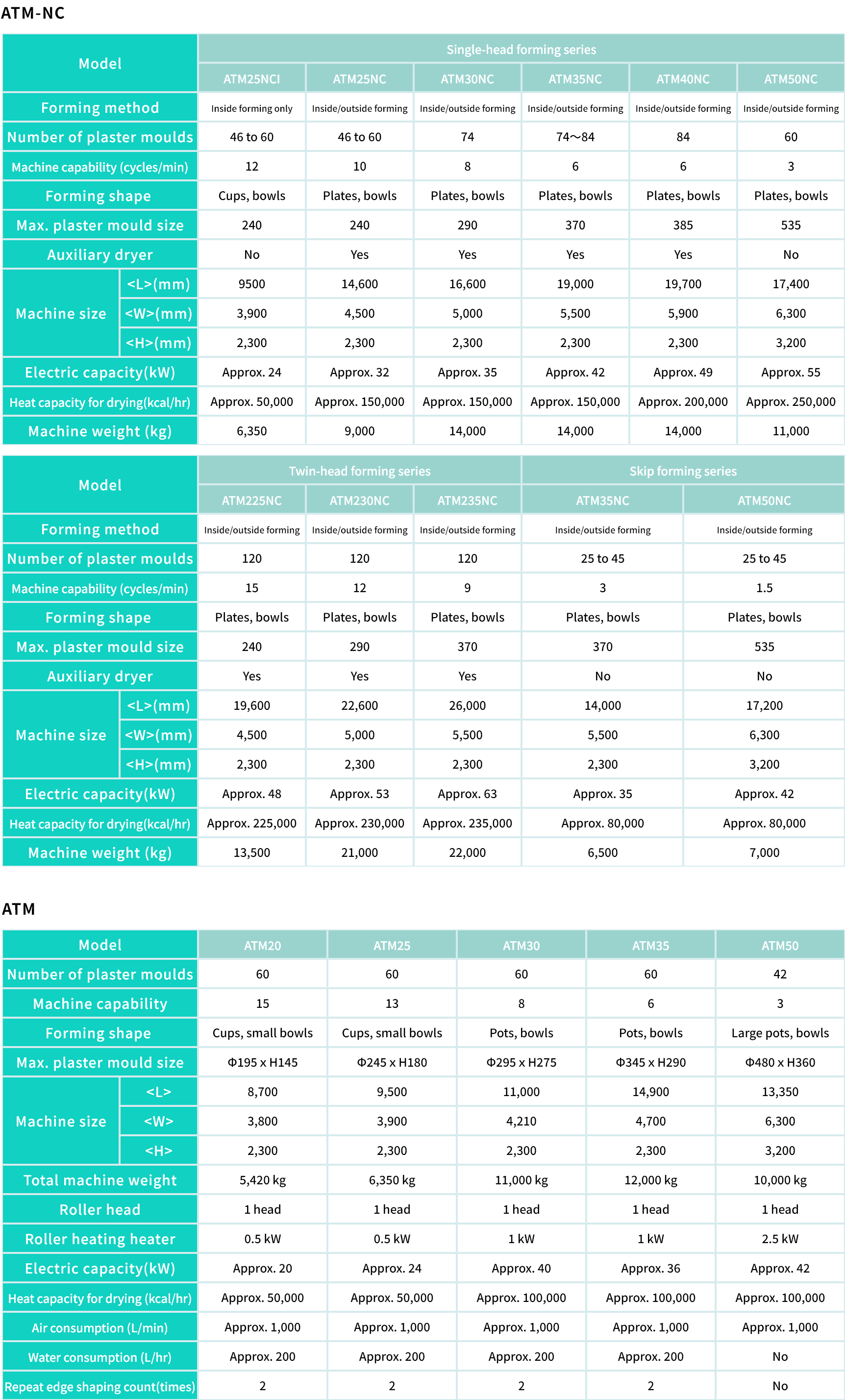

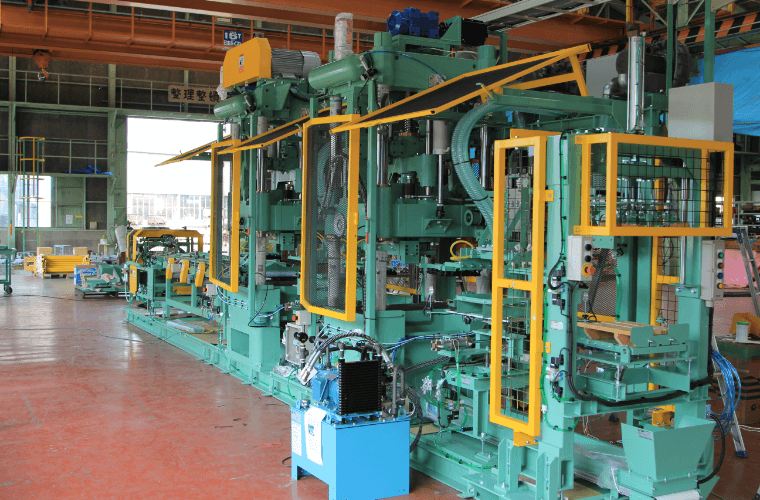

Press for roofing tiles

This press is capable of forming all kinds of product shapes and meeting tight customer production schedules. Types include a hydraulic type, cam type, crank type, and screw type.

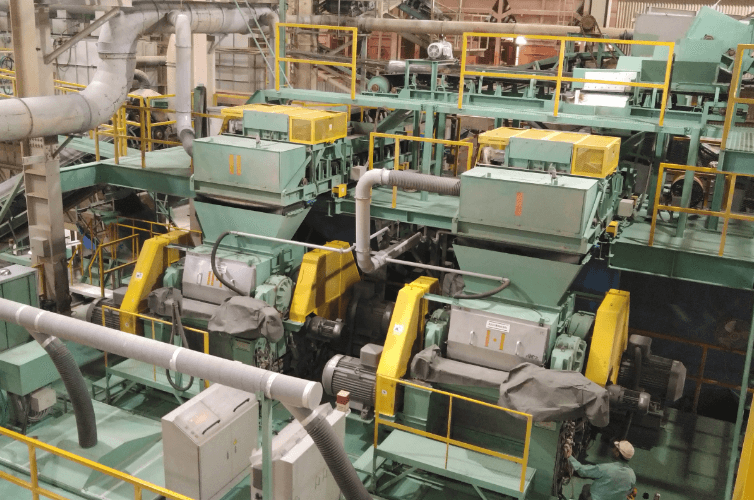

Feeding, mixing, and pulverizing equipment

TAKAHAMA boasts a range of equipment for feeding, mixing, and pulverizing that is necessary for mixing raw materials.

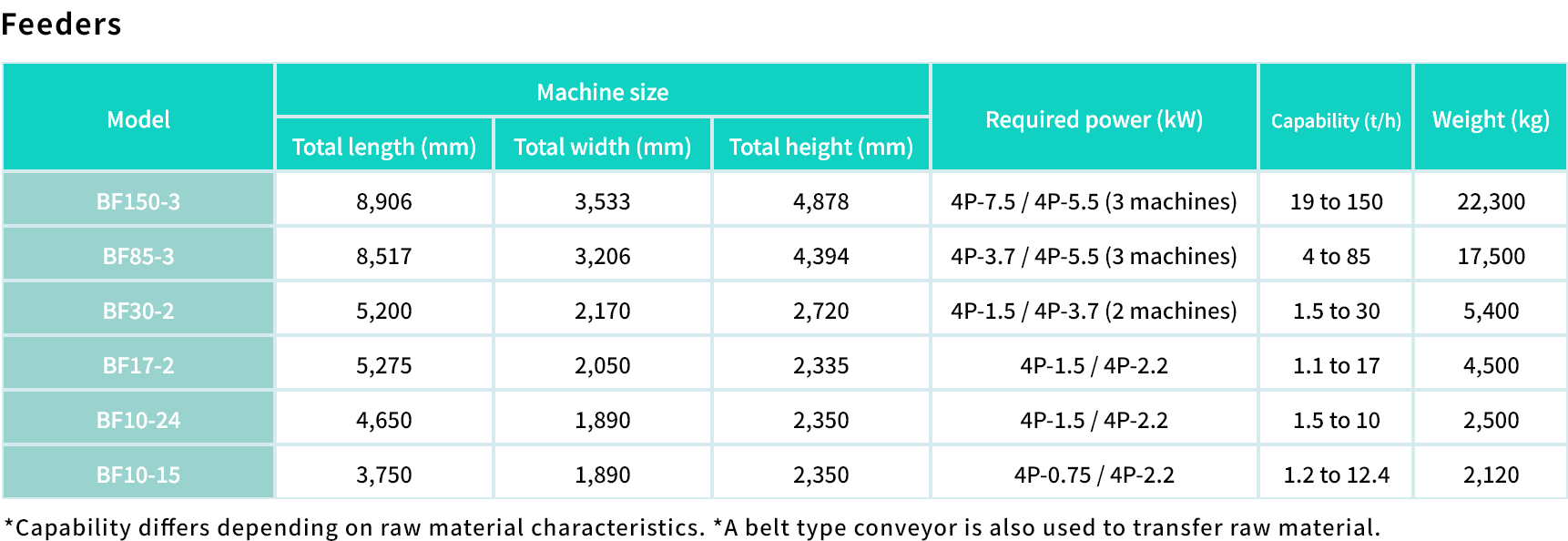

Feeders

Our feeders can supply fixed quantities at set feedrate. The machine can be selected based on whether the raw material is solid or powder, etc. They can be installed both indoors and outdoors.

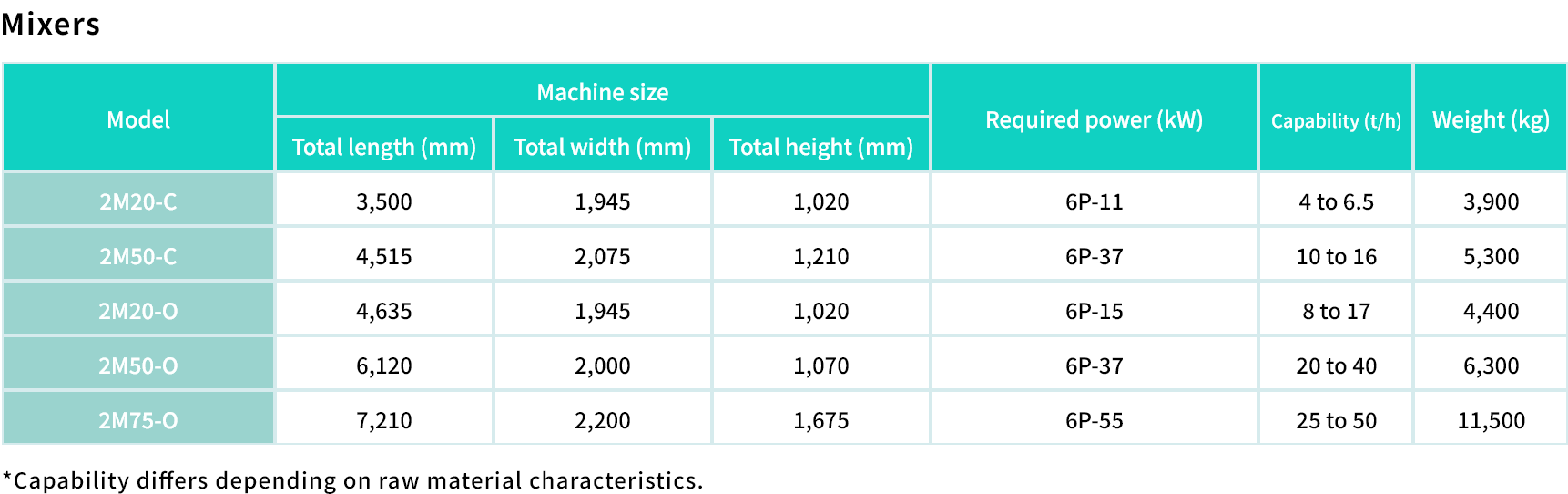

Mixers

A 2-axis mechanism is used to mix raw material continuously while maintaining a stable mixing condition. Water can also be added to adjust the moisture. An open type, closed type, or vacuum type can be selected depending on the raw material and purpose.

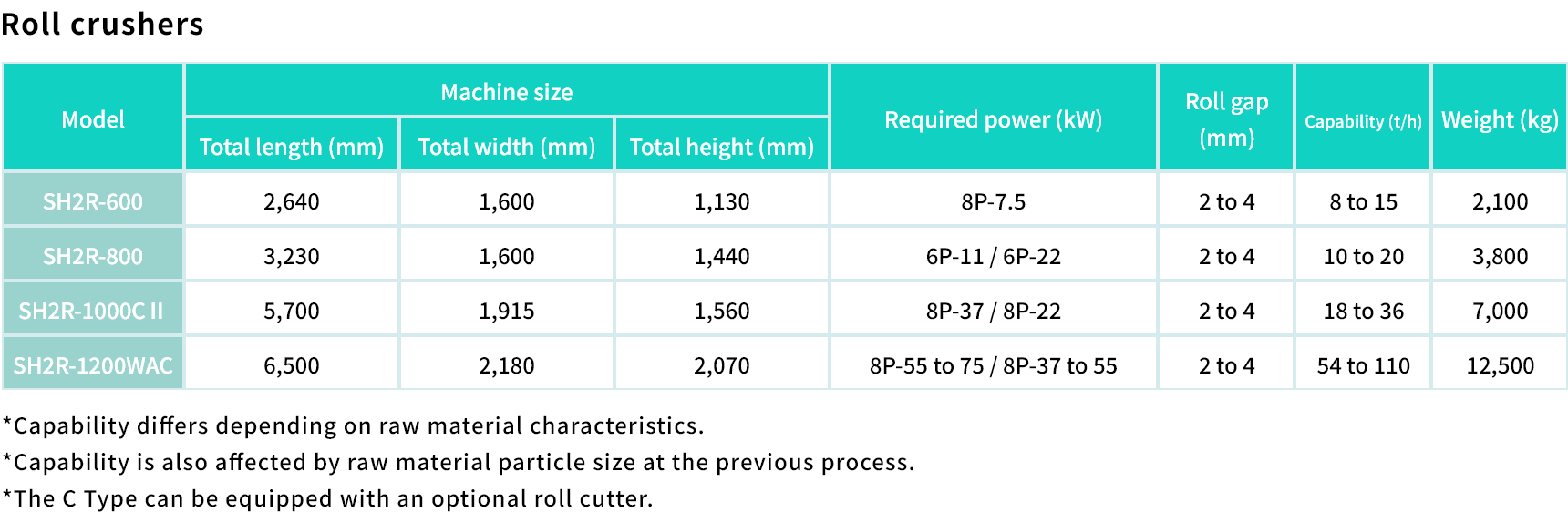

Roll crusher

This machine pulverizes small stones and rocky soil contained in original soil by rotating 2 rollers.

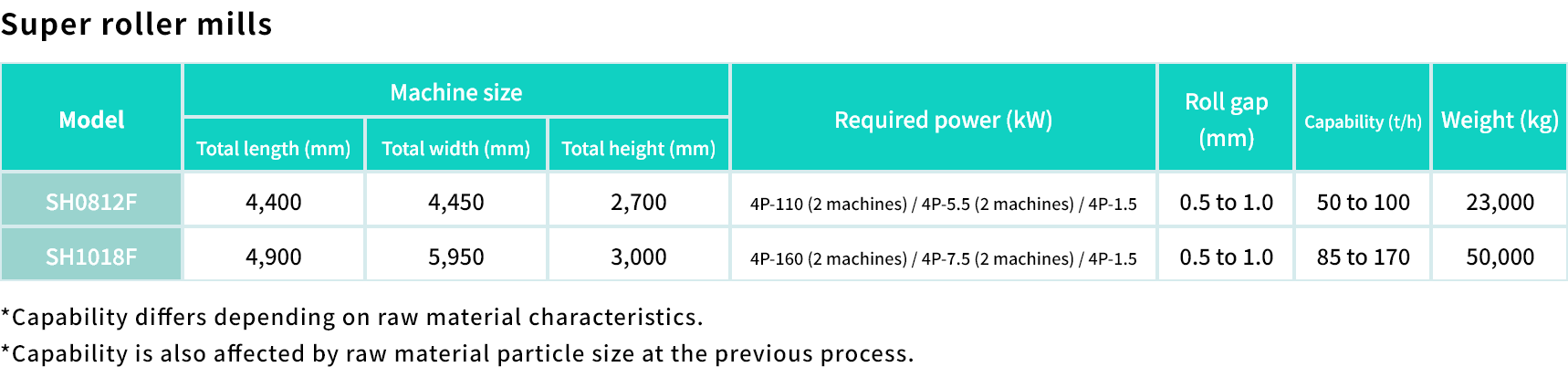

Super roller mills

TAKAHAMA’s supper roller mills offer a level of pulverizing and processing capability several times greater than that of the roll crusher, and the model can be selected to suit the raw material, capability, or application.

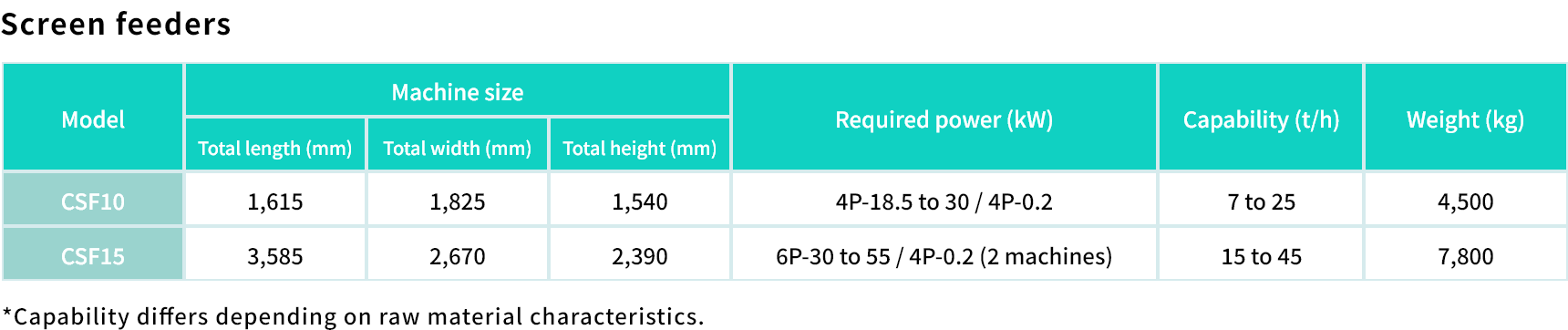

Screen feeder

“Peculiarities” inherent in original sand can be removed by pushing mixed original sand from a mesh. Foreign material is then eliminated at the next process.

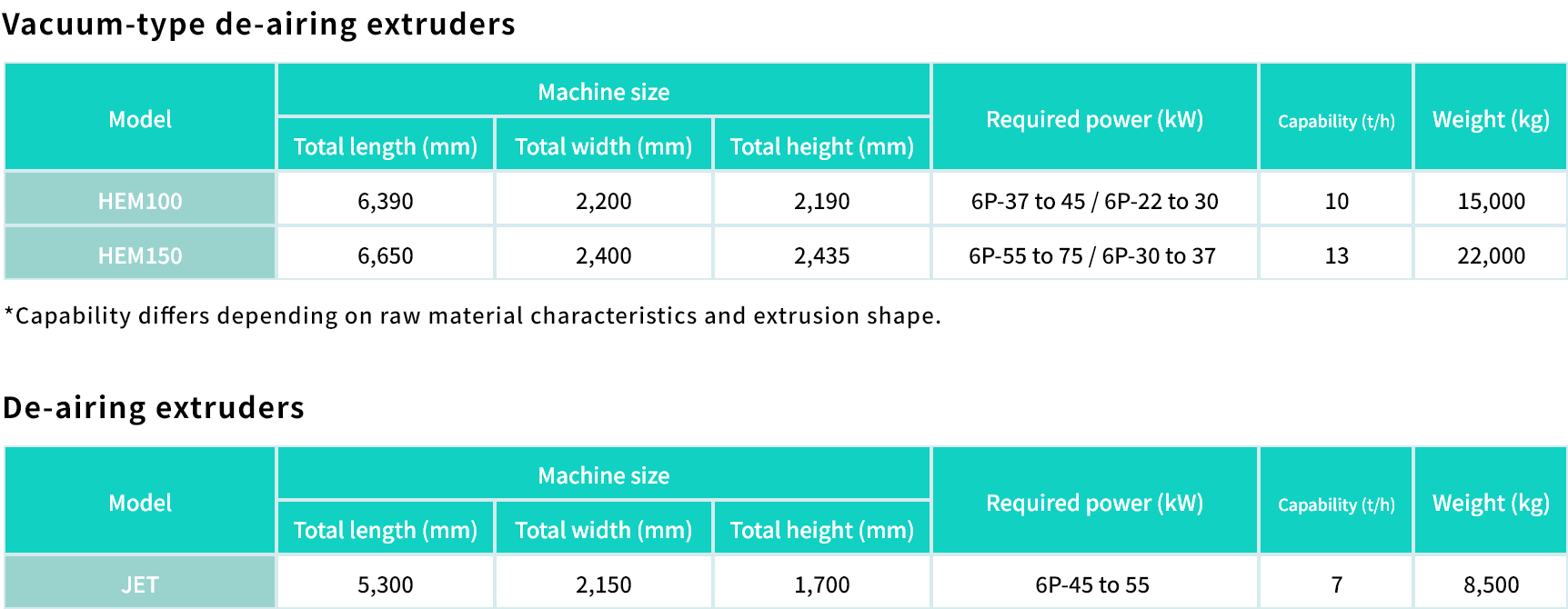

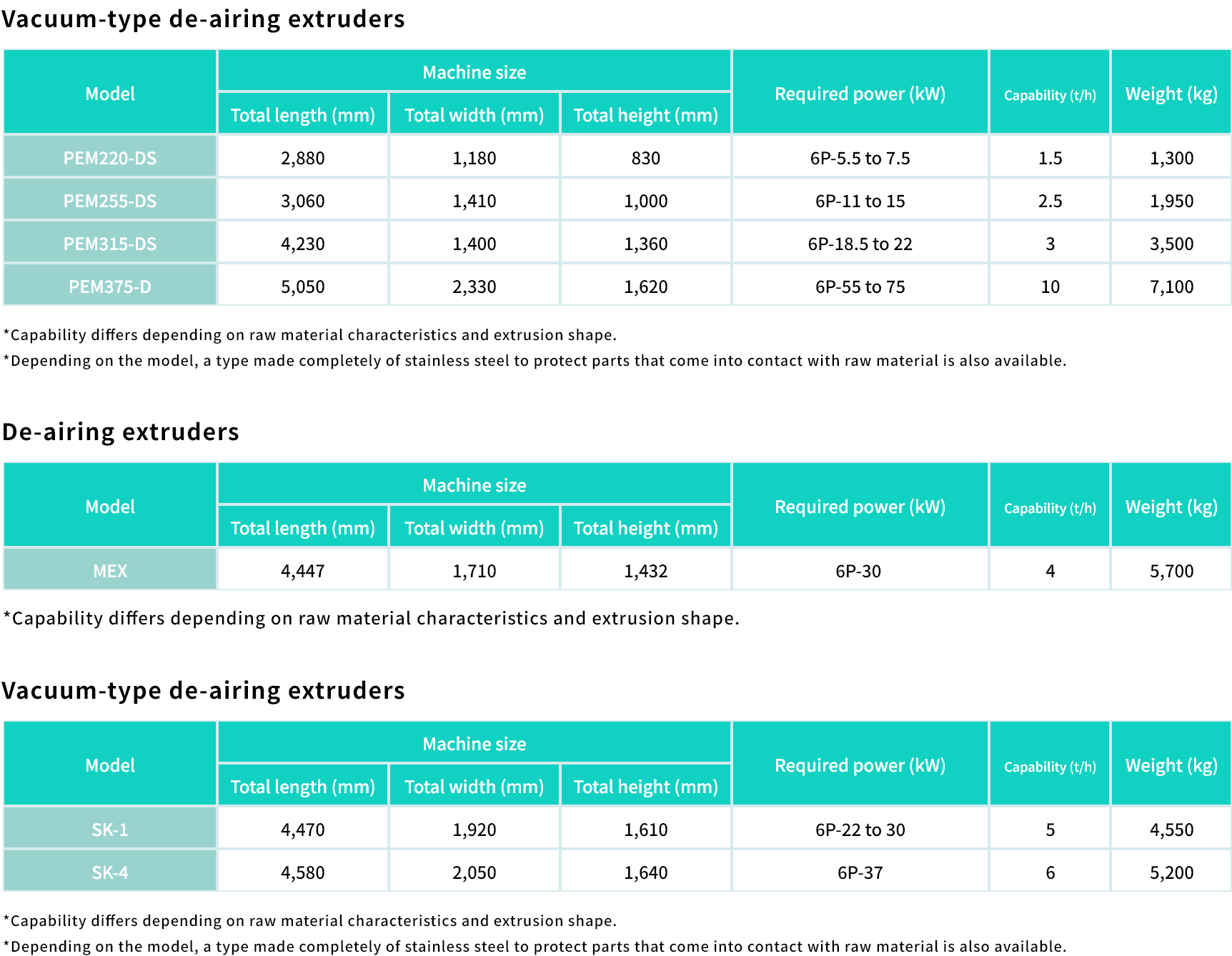

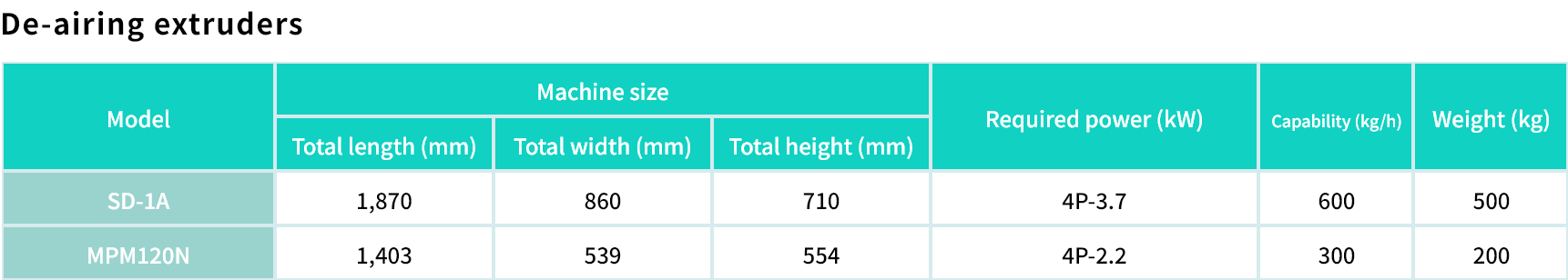

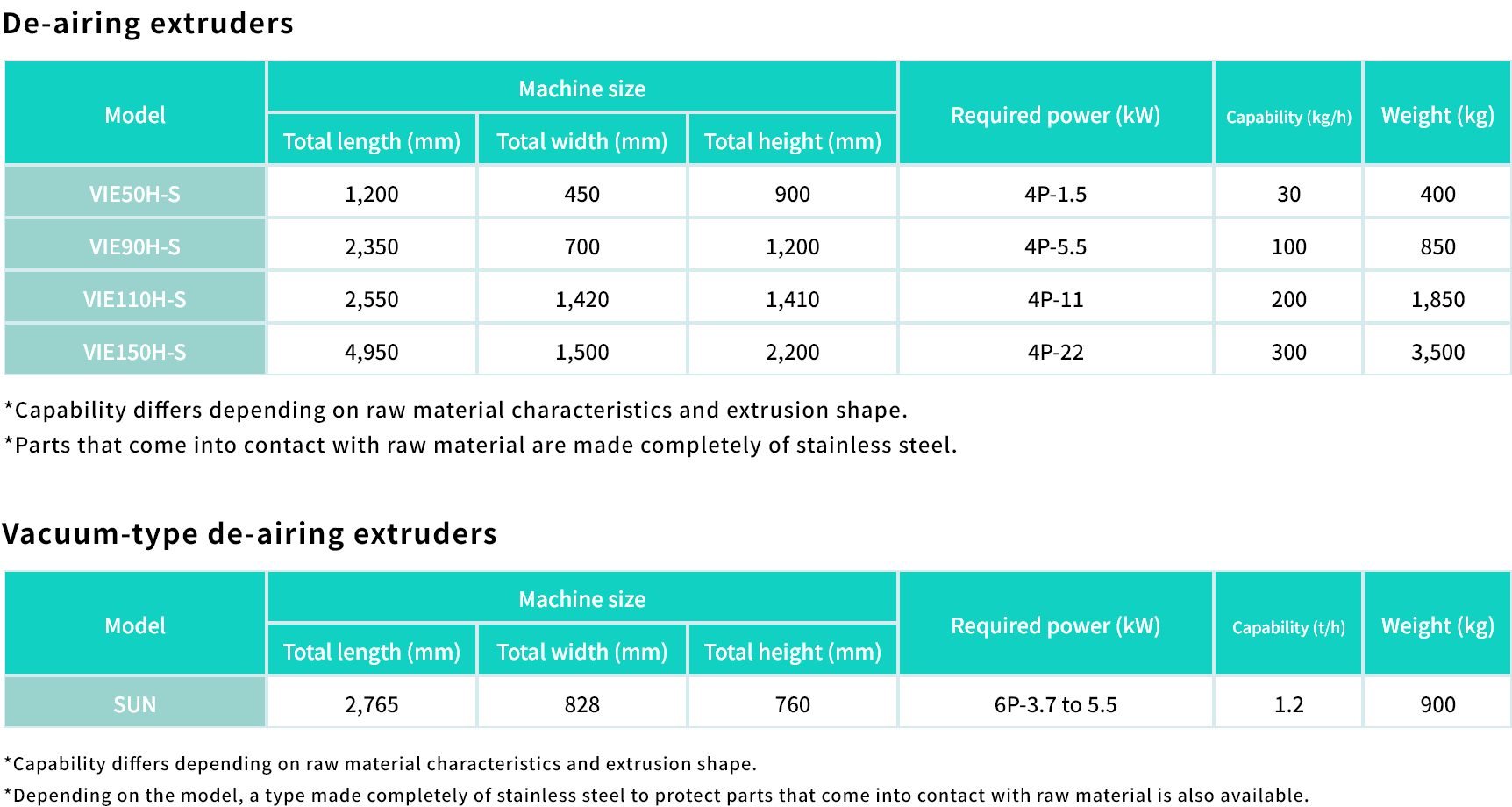

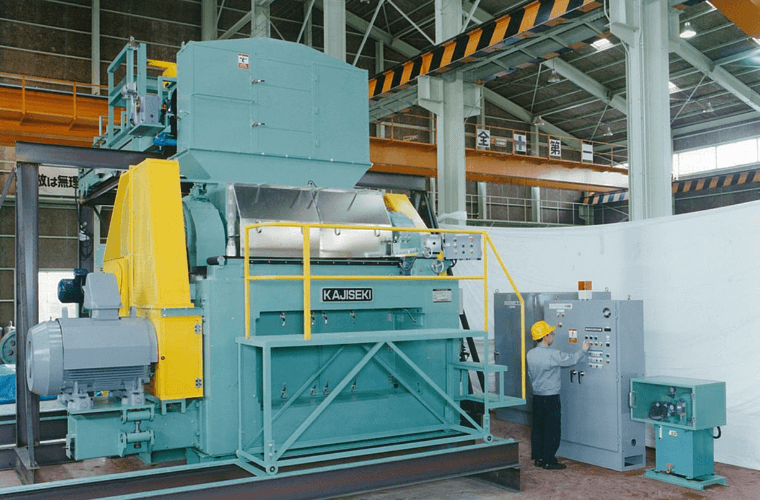

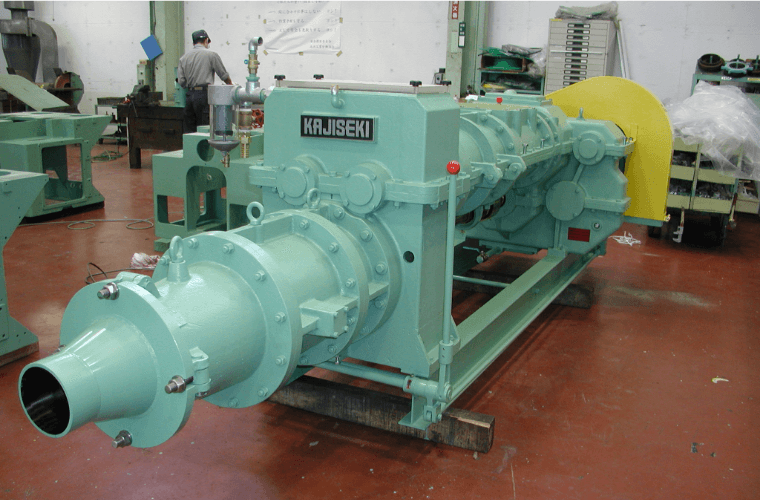

De-airing extruders, extruders

Raw material has various characteristics, and there are various methods of extrusion to suit the material.

TAKAHAMA offers a lineup of different extruders for different materials.

Applications: Ceramics, roofing tiles, tiles, bricks,

plant pots, insulators, honeycomb

Large machines

Our HEM type is a vacuum-type de-airing extruder ideal for the extrusion of relatively standard raw material (clay). The arm shaft has a 2-axis mixing process.

The JET type is more rigid than the HEM type, and is a high-pressure extrusion machine capable of extruding hard original sand.

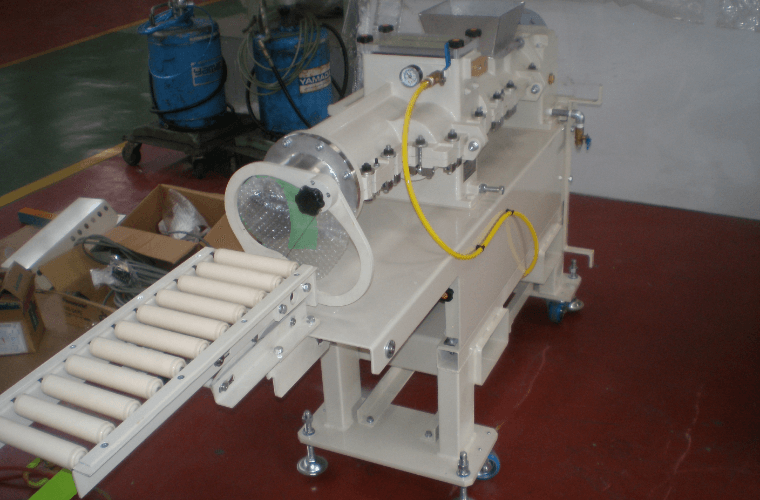

Medium-sized machines

Our PEM type machine has a completely stainless steel type to ensure that the parts that come into contact with raw material do not rust. We also have a special double screen type to fragment the raw material. Our MEX type is a medium-sized version of the large JET type. Our SK type is a medium-sized version of the HEM type.

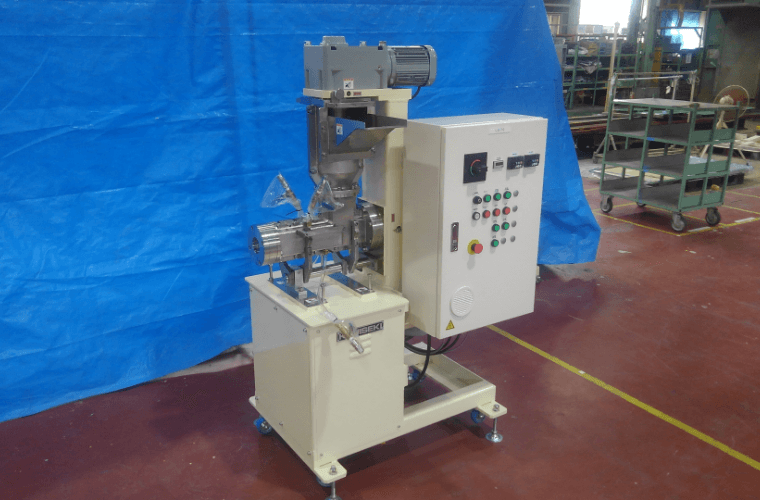

Compact machines

Our compact machines are perfect for small-lot production. The raw material filling area has a 2-axis construction, and the section after vacuum deaeration has a single-axis extrusion construction. These machines are best suited to the small quantity production of various raw materials and for test purposes. The machines are equipped with a single auger with shaft that can be removed for easy cleaning. We also offer a completely stainless steel type.

Test machine

TAKAHAMA offers a high-pressure extruder developed for testing. The parts that come into contact with raw material are made completely of stainless steel, and there is a single auger with shaft that can be removed for easy cleaning. The jacket is capable of both heating and cooling.

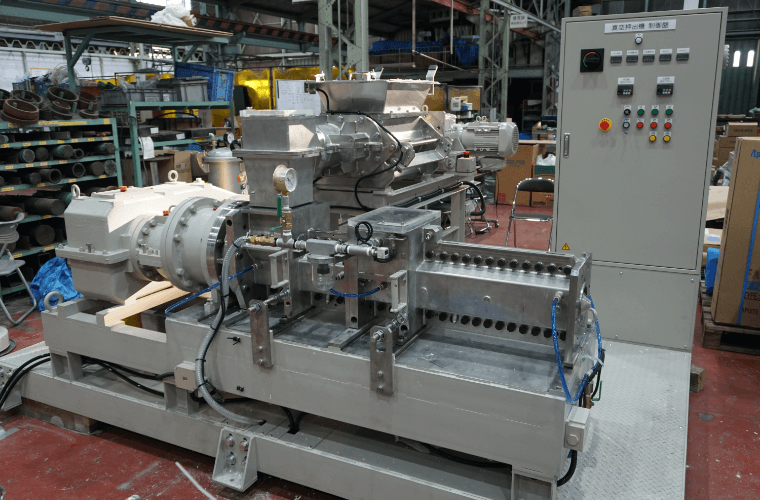

High-pressure machine

This high-pressure extruder is ideally suited to extrusion for fine ceramics which require precision such as insulators and honeycomb. The parts that come into contact with raw material are made completely of stainless steel, and the jacket is capable of both heating and cooling. We also offer a vertical type machine which may be used depending on the product conditions after extrusion.

Drying equipment

TAKAHAMA designs and manufactures drying equipment to suit conditions such as production capacity, product type, and installation space.

Tunnels

TAKAHAMA uses a robot system for loading and unloading, and humidity is controlled at the PC.

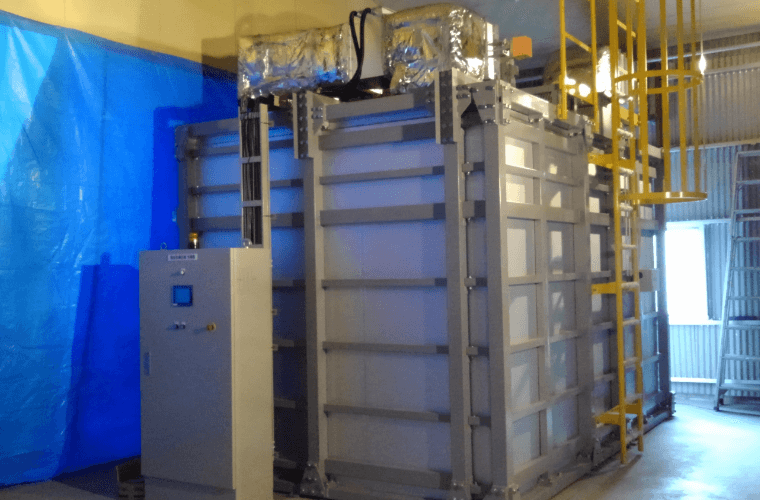

Batch

This space-saving machine is perfect for high-mix low-volume production, and humidity is controlled at the PC.

Transfer robots

TAKAHAMA designs and manufactures transfer robots to suit conditions such as production capacity, product type, and installation space.

Sagger loading machine

This machine is used to supply saggers for baking finished products to a loading unit. The machine can be installed in the minimum of space, and can be configured flexibly to suit various types of production. TAKAHAMA designs and manufactures these machines for both general-purpose and special-purpose needs.

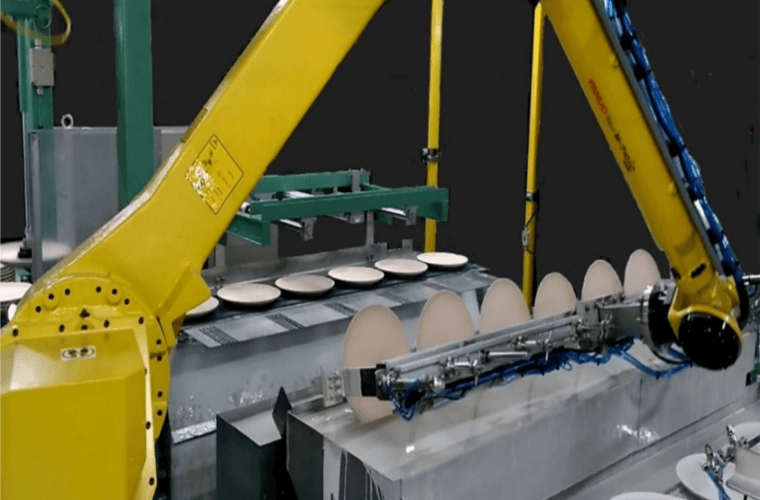

Palletizing robot

The heavy labor required for loading is performed by a robot.

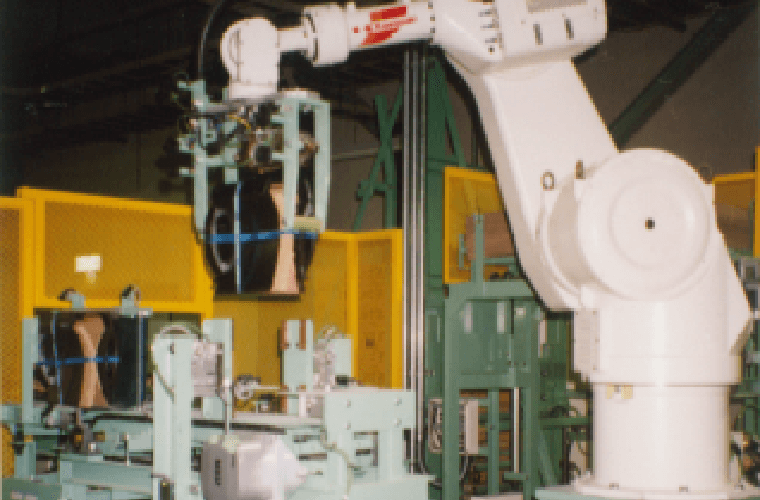

Glazing robot

The glazing work that has until not been performed manually by craftsmen is now reproduced with a robot. This ensures uniform glazing, and offers a solution to labor shortages.